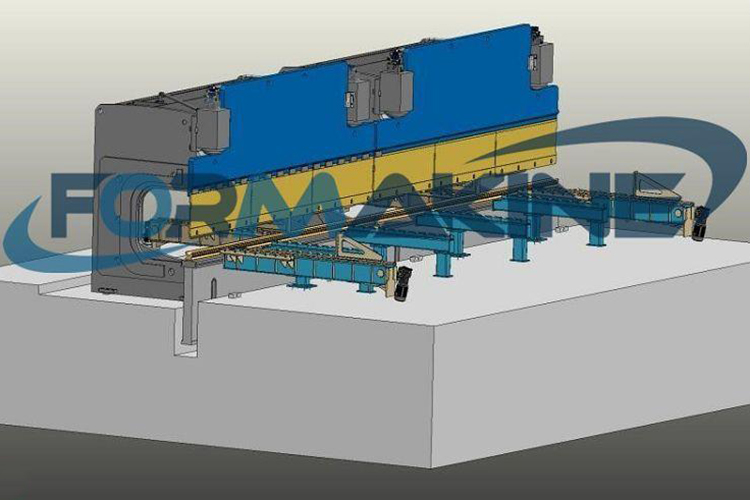

Safe CNC Synchro Hydraulic Tandem Press Brake

Product Description

Formakine CNC Tandem pressbrakes adopting 2 units CNC Synchro pressbrakes, using DELEM DA58T 2D graphical controller, 2 units cnc press brakes can work separately for bending metal sheet profiles, also you can switch tandem links to tandem press brake running for bending 8m long sheet metal profiles.

Our Tandem Press Brakes can be customized to your needs and outfitted with advanced CNC controllers, like DELEM DA58T, DA66T, ESA S640, ESA S650, ESA S660W, CYBELEC ModEva 15T.

Customized tonnage and metal bending length configurations are available.

Especially well-suited for forming extra-long pieces, such as 8m/10m/12m workpieces.

Full synchronization for 2 units pressbrakes, 3 units pressbrakes working together or separately.

Each machine can also be operated independently with the flip of a switch – with no de-mounting or physical disconnections between presses required.

Product Features

With DELEM DA58T 2D Graphic Touch screen CNC Press Brake controller.

CNC Press Brakes is overall welded and designed using SOLID WORKS 3D programming,use German hydraulic proportional valves technology and linear encoder mounted on two sides of machine.

The main frame made of steel welded constructions,has been designed according minimum stretch and optimum resistance standards.

Accuracy is further ensured by mounting the linear encoders on a C frame connected to the bed, rather than directly on the side frames, so deflection of the side frames and pressure loads do not affect positioning.

Using CNC boring&milling machine to fabricate the main parts.

Each time the machine automatically goes to the reference.

Automatically pressing force adjustment according to bending plate.

Automatic position settings and retract functions,each step in bending program.

Programmable and automatically maximum force limitations.

DELEM CNC automatic controlled back gauge with Servo motor and drive, ball screw and linear guide cnc press brake back gauge made in china.

Technical Parameter

| Model | 2-160/3200 | 2-160/4000 | 2-250/3200 | 2-250/4000 | 2-320/4000 | 2-320/6000 | 2-400/4000 | 2-400/6000 | 2-600/6000 | 2-800/6000 |

| Nominal Pressure Of Machine(KN) | 2*1600 | 2*1600 | 2*2500 | 2*2500 | 2*3200 | 2*3200 | 2*4000 | 2*4000 | 2*6000 | 2*8000 |

| Length Of Working Table(Mm) | 2*3200 | 2*4000 | 2*3200 | 2*4000 | 2*4000 | 2*6000 | 2*4000 | 2*6000 | 2*6000 | 2*8000 |

| Throat Depth(Mm) | 2550 | 3350 | 2700 | 3300 | 3300 | 5300 | 3100 | 5200 | 5200 | 7200 |

| Throat Depth(Mm) | 320 | 320 | 400 | 400 | 400 | 400 | 400 | 400 | 900 | 1100 |

| Ram Stroks(Mm) | 200 | 200 | 250 | 250 | 250 | 250 | 320 | 320 | 320 | 420 |

| Max.Open Height Between Working Table And Ram(Mm) | 500 | 500 | 560 | 560 | 560 | 560 | 625 | 625 | 1100 | 1200 |

| Power Of Main Motor(Kw) | 2*11 | 2*11 | 2*15 | 2*15 | 2*22 | 2*22 | 2*37 | 2*37 | 2*55 | 2*57 |

| Overall Dimensions(Mm) | 2*14702045

3080 |

2*45452045

3080 |

2*40002250

4060 |

2*48002250

4060 |

2*40602570

4560 |

2*60602570

4560 |

2*40503240

3880 |

2*60503240

3880 |

2*60503240

3880 |

2*80503840

8000 |

| Weight Of Machine(Kg) | 2*10200 | 2*11900 | 2*19200 | 2*20000 | 2*22000 | 2*27020 | 2*29950 | 2*42000 | 2*130000 | 2*190000 |

Packaging & Shipping