NC Hydraulic Plate Guillotine Shearing Machine

Product performance

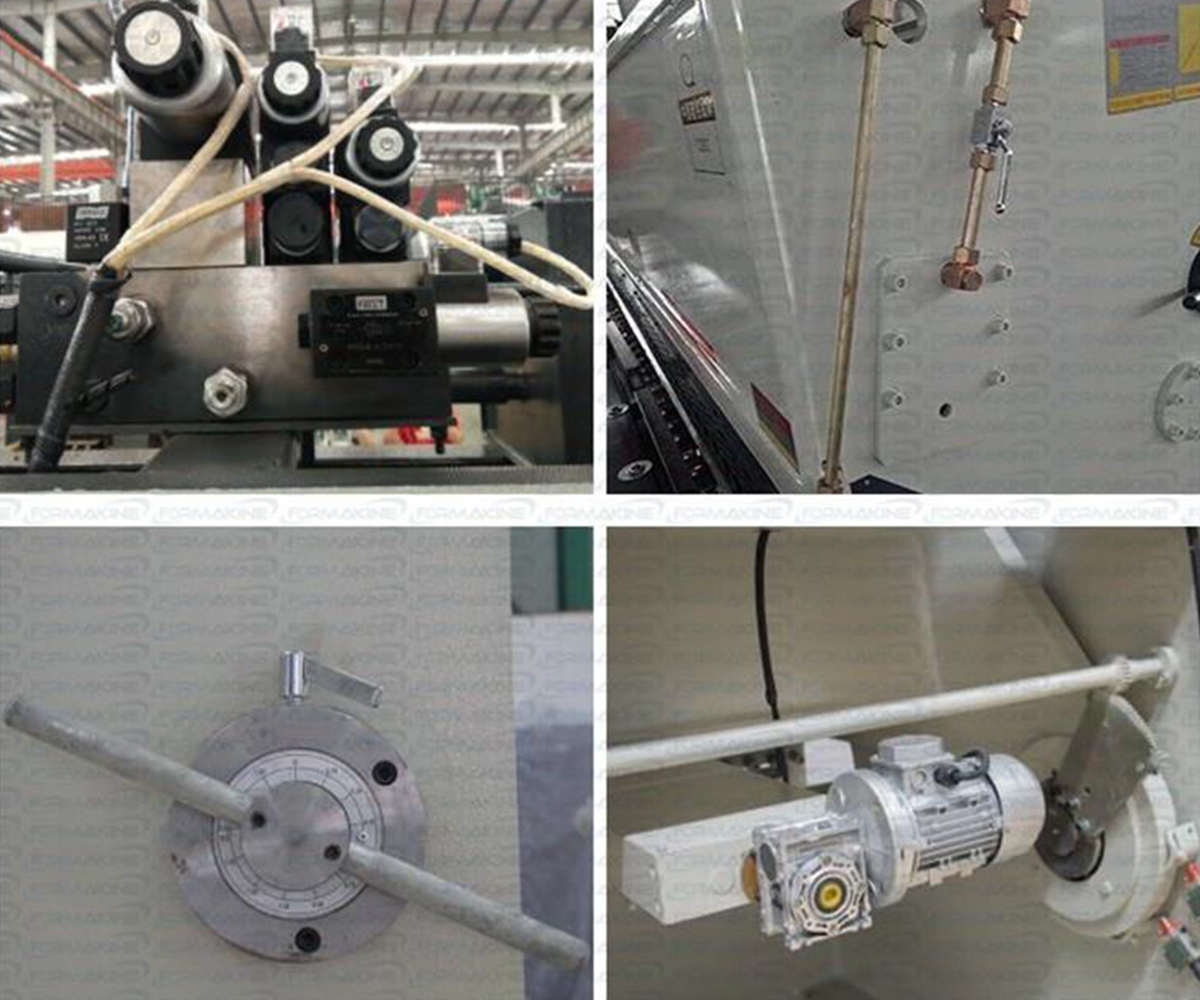

1.Sheet plate welded structure is adopted, with hydraulic transmission and accumulator return, typical of an easy operation, reliable performance, and nice appearance.

2.Indication by indicator is provided for adjustment of blade clearance, for a handy and prompy adjustment.

3.Alignment device with lighting and control device for shearing stroke are set, with a handy and prompt adjustment.

4.Rolling material support ball is provided,to minimize fish tail with sheet bar and to reduce frictional resistance.

5.The rear stopper is fitted with electric adjustment and manual adjustment devices, and digital display device is available for display of size of stopper and times of shearing.

6.The main engine uses the QC12Y series type, equips simple CNC system

7.Has the rear bumper material position numerical code to demonstrate soft spacing; one-way positioning; gap prompt, and qutomatic count for cutting times

8.The backgauge is equipped with encoder, coordinated nummerical code display system, which make the demonstration of backgauge position more accurate, thus further enhance the cutting precision.

Technical Parameters

|

Model |

Cutting Thickness |

Cutting Length |

Cutting Angle |

Travel Times |

Bumper Distance |

Throat Depth |

Power |

Dimension |

|

|

(Mm) |

(Mm) |

(°) |

|

(Mm) |

(Mm) |

(KW) |

(L×W×H) (Mm) |

|

6×2500 |

6 |

2500 |

0.5°-1°30’ |

14 |

600 |

80 |

7.5 |

3100×1725×1960 |

|

6×3200 |

6 |

3200 |

0.5°-1°30’ |

12 |

600 |

80 |

7.5 |

3650×1750×1980 |

|

6×4000 |

6 |

4000 |

0.5°-1°30’ |

10 |

600 |

80 |

7.5 |

4650×1780×2075 |

|

6×5000 |

6 |

5000 |

0.5°-1°30 |

8 |

600 |

80 |

7.5 |

5650×1830×2250 |

|

6×6000 |

6 |

6000 |

0.5°-1°30’ |

8 |

600 |

80 |

7.5 |

6650×1890×2380 |

|

8×2500 |

8 |

2500 |

0.5°-1°30’ |

14 |

600 |

80 |

7.5 |

3100×1725×1960 |

|

8×3200 |

8 |

3200 |

0.5°-1°30’ |

12 |

600 |

80 |

7.5 |

3850×1750×1980 |

|

8×4000 |

8 |

4000 |

0.5°-1°30’’ |

10 |

600 |

80 |

7.5 |

4650×1850×2075 |

|

8×5000 |

8 |

5000 |

0.5°-2° |

7 |

600 |

80 |

15 |

5805×2000×2500 |

|

8×6000 |

8 |

6000 |

0.5°-2° |

7 |

600 |

100 |

15 |

6805×2115×2715 |

|

10×2500 |

10 |

2500 |

0.5°-2°30’ |

10 |

600 |

120 |

15 |

3195×1800×2210 |

|

10×3200 |

10 |

3200 |

0.5°-2°30’ |

8 |

600 |

120 |

15 |

3895×1800×2240 |

|

10×4000 |

10 |

4000 |

0.5°-2°30’ |

6 |

600 |

120 |

15 |

4695×1930×2275 |

|

10×5000 |

10 |

5000 |

0.5°-2°30’ |

5 |

600 |

120 |

15 |

5905×2115×2715 |

|

10×6000 |

10 |

6000 |

0.5°-2°30’ |

5 |

600 |

120 |

15 |

6905×2215×2800 |

|

12×2500 |

12 |

2500 |

0.5°-2°30’ |

10 |

600 |

120 |

15 |

3195×1800×2210 |

|

12×3200 |

12 |

3200 |

0.5°-2°30’ |

8 |

600 |

120 |

15 |

3895×1800×2240 |

|

12×4000 |

12 |

4000 |

0.5°-2°30’ |

6 |

600 |

120 |

15 |

4710×1950×2485 |

|

12×5000 |

12 |

5000 |

0.5°-2°30’ |

5 |

600 |

120 |

18.5 |

5905×2115×2800 |

|

12×6000 |

12 |

6000 |

0.5°-2°30’ |

4 |

600 |

120 |

18.5 |

7000×2300×3100 |

|

16×2500 |

16 |

2500 |

0.5°-2°30’ |

8 |

600 |

120 |

15 |

3215×1880×2340 |

|

16×3200 |

16 |

3200 |

0.5°-2°30’ |

7 |

600 |

120 |

15 |

3915×1880×2445 |

|

16×4000 |

16 |

4000 |

0.5°-2°30’ |

6 |

600 |

120 |

15 |

4715×1950×2590 |

|

16×5000 |

16 |

5000 |

0.5°-3° |

5 |

600 |

120 |

22 |

6000×2300×3000 |

Packing & Delivery