Hydraulic Stainless Steel Tube Bending Machine

Product Features

1) Using the microcomputer control, automatic bending.

2) On the bending arm and control pannel installed emergengcy stop button to avoid accident.

3) Dialogue operation, easy to understand.

4) Partition hypothesis speed, pipe-bending high precision up to ±0.15°.

5) Multi-group programs, multi-angle settings, make your operation simple.

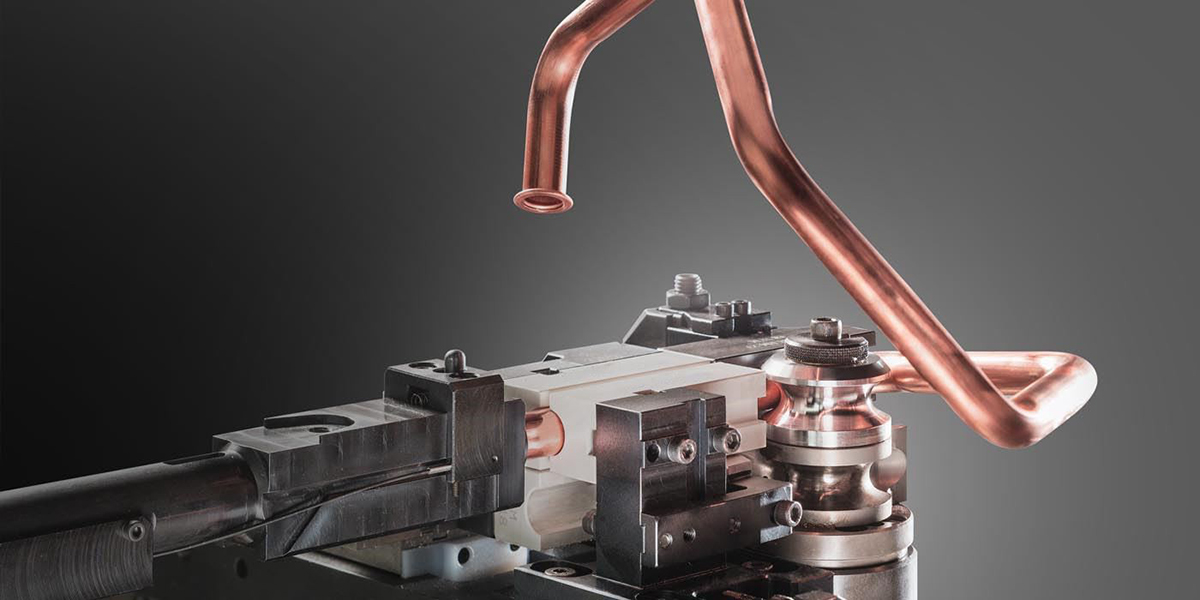

6) The mandrel automatically in and out, saving time.

7) Suitable for bending steel pipe, stainless steel pipe, copper pipe, aluminum pipe, profiles and etc.

8) Optional auxiliary push die, low returning-core function, can bend thin pipes.

9) Special optional fitting: special mould, anti-wrinkle mould, auxiliary push installation, etc.

Product Application

Operated by NC control unit, with fast bending speed ,16 groups of bending information can be stored, multiple different angles can be finished once. It was widely used in mass production of standardized products, such as Automobile spare parts (brake line, bumper bar, silencer and etc.), fitness equipment, sanitary equipment, vent-pipe, petroleum/water pipeline, shipbuilding and chemical Industries.

Standard Accessories

1) One pair of standard mould (wheel mould, clamping mould and sliding plate mould)

2) One set of common tools

Special Accessories For Option.

Auxiliary pushing device, core rod, wrinkle-proof mould, shaped mould, forming mould

Tailor made mould for shape like square tube, elliptical tube, plum blossom-shape tube, shaped tube, U-steel, angle bar, I-steel and flat steel, etc.

Technical Parameters

| Max Bending Capacity | Ø50mmX3 |

| Max Bending Radius | 220mm |

| Min Bending Radius | According To Pipe Diameter |

| Max Bending Degree | 185° |

| Max Feeding Length | 3000mm |

| Bending Speed | Max 85°/S |

| Rotary Speed | Max 180°/S |

| Feeding Speed | Max 700mm/S |

| Bending Accuracy | ±0.1° |

| Rotary Accuracy | ±0.1° |

| Feeding Accuracy | ±0.1mm |

| Information Inputting Method | Axis (Y,B,C) |

| Bending Method | Hydraulic Bending(2A), Servo Bending(3A) |

| Rotary Servo Motor Power | 750W |

| Feeding Servo Motor Power | 1300W |

| Motor Power | 5.5KW |

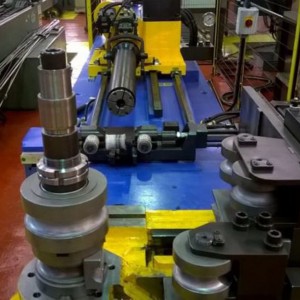

Picture Display

Realted Product

Delivery