High Speed Vertical Machining Center

Product Description

Standard configuration of import control systems and servos such as, Fanuc, Mitsubishi and Siemens to provide overall solutions for high-speed and high-precision processing users.

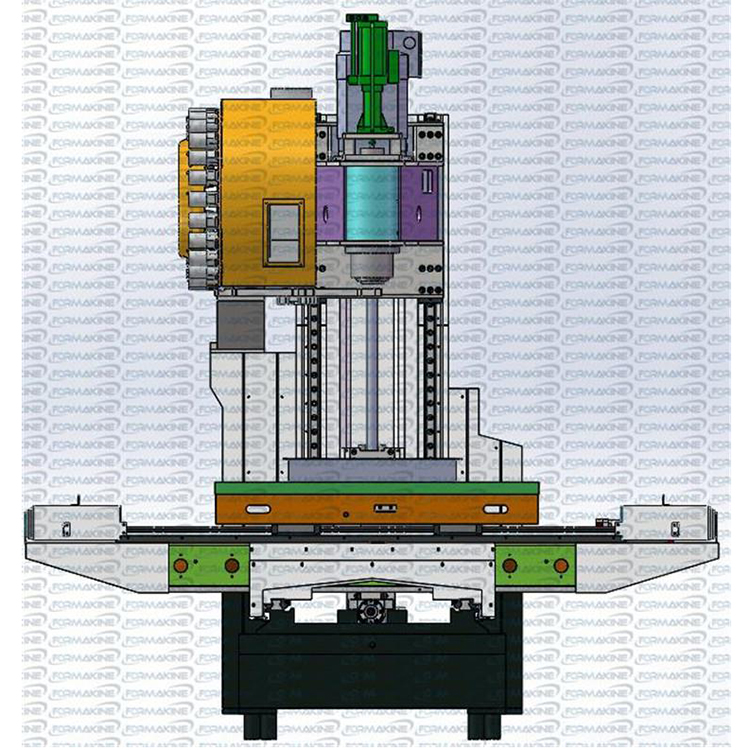

The main castings of high rigidity machine bed and columns are made of mineral material, guarantee machine damping capacity and stability.

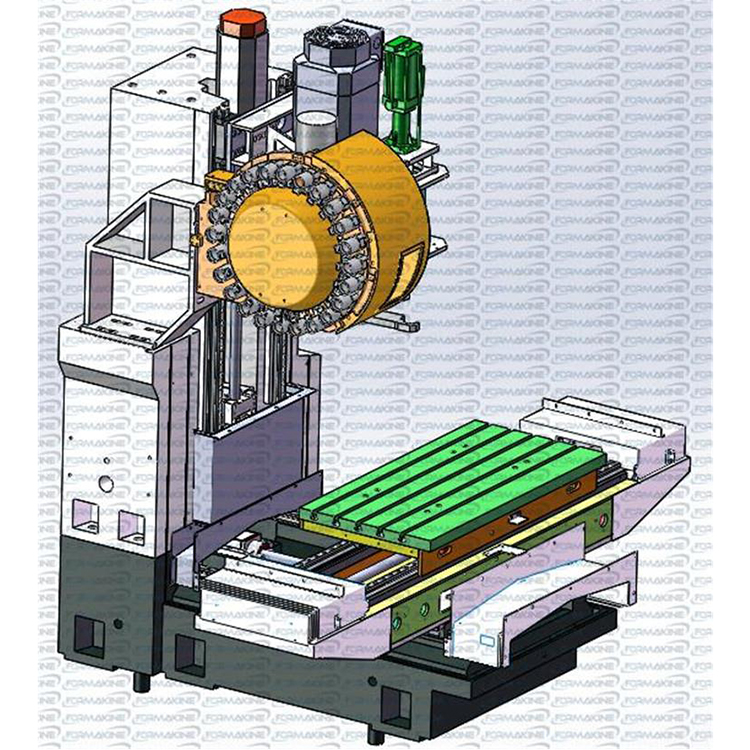

The standard THK or HIWIN high precision screw rods , PMI linear guide rail and NSK or FAG bearing are assembled with high precision. The repeated positioning accuracy is 0.005mm and the positioning accuracy is 0.008mm.

The spindle is equipped with 8000rpm, 12000 rpm for high-speed spindle and 24000 rpm for motorized spindle, and high-precision grating with positioning accuracy of 0.004.

Controlling thermal deformation: selecting and matching measures to prevent thermal deformation, such as spindle oil cooling, screw water cooling, electric cabinet temperature control, etc.

Technical Parameters

|

Travel X-Y-Z |

Mm |

1100-610-610 |

1100-610-610 |

|

Spindle Drive Type |

Rpm |

Belt Typre |

Direct Type |

|

Spindle Max.Speed |

KW |

8000 |

8000 |

|

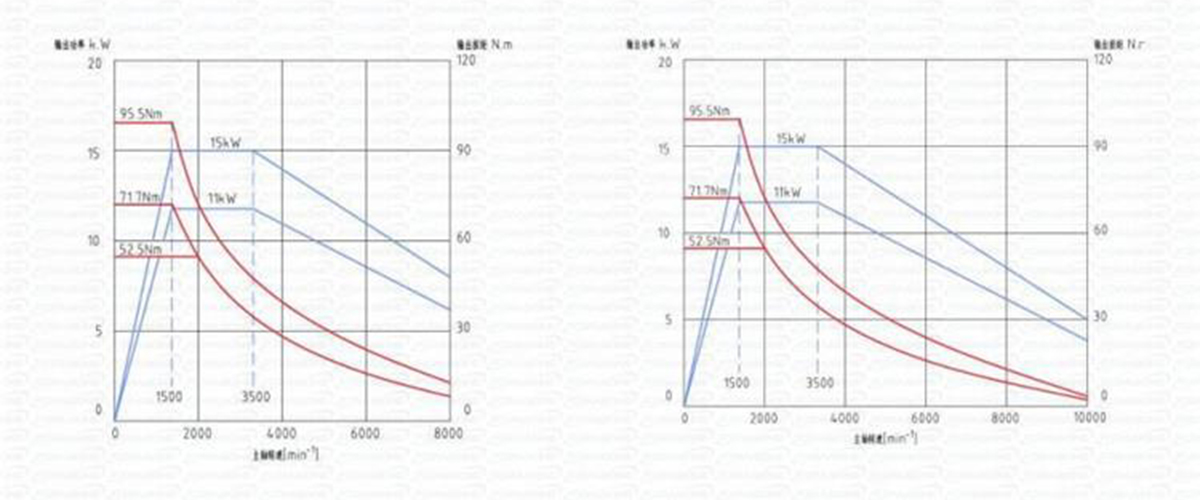

Spindle Power |

|

11/15 |

11/15 |

|

Controller |

|

FANUC 0i MF |

FANUC 0i MF |

|

Spindle Nose-Table |

Mm |

150-760 |

150-760 |

|

Table Size(LxW) |

Mm |

1200×600 |

1200×600 |

|

T-Slot(SizexNo.XPath) |

Mm |

18×5×100 |

18×5×100 |

|

Load Capacity |

Kg |

1000 |

1000 |

|

Traverse Speed |

M/Min |

36/36/24 |

36/36/24 |

|

Cutting Speed |

Mm/Min |

1-12000 |

1-12000 |

|

3 Axis Positioning Accuracy |

Mm |

±0.008 Full Travel |

±0.008 Full Travel |

|

Repeatability |

Mm |

±0.005 Full Travel |

±0.005 Full Travel |

|

Type/Capacity |

|

Disc/24T |

Disc/24T |

|

Max.Tool Size(Full /Unfull/Length) |

Mm |

Φ78/Φ150/ 300 |

Φ78/Φ150/ 300 |

|

Max. Tool Weight |

Kg |

8 |

8 |

|

Airpressure |

MPa |

0.65 |

0.65 |

|

Power Consumption |

KVA |

25 |

25 |

|

Machine Weight |

Kg |

7000 |

7000 |

|

Machine Size (LxWxH) |

Mm |

2900×2250×3200 |

2900×2250×3200 |

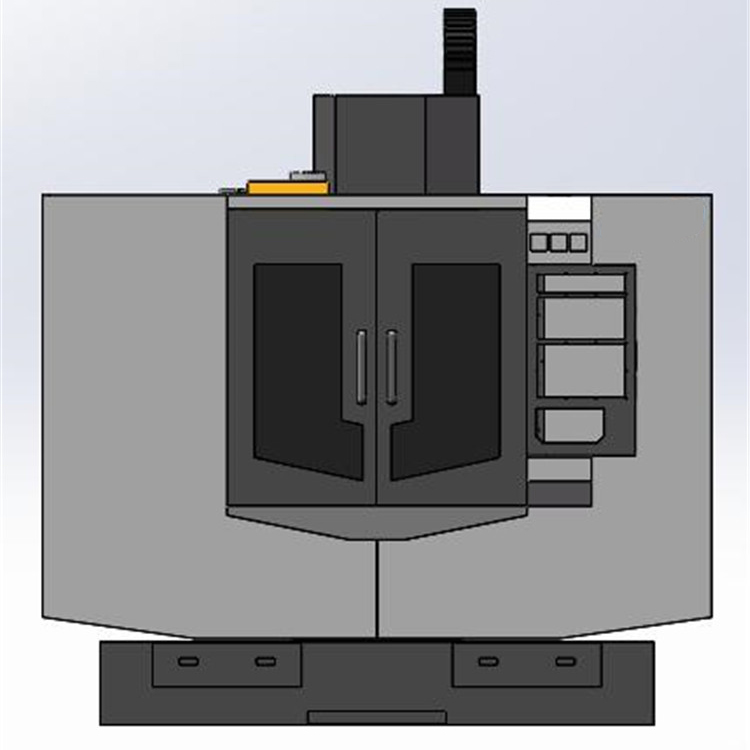

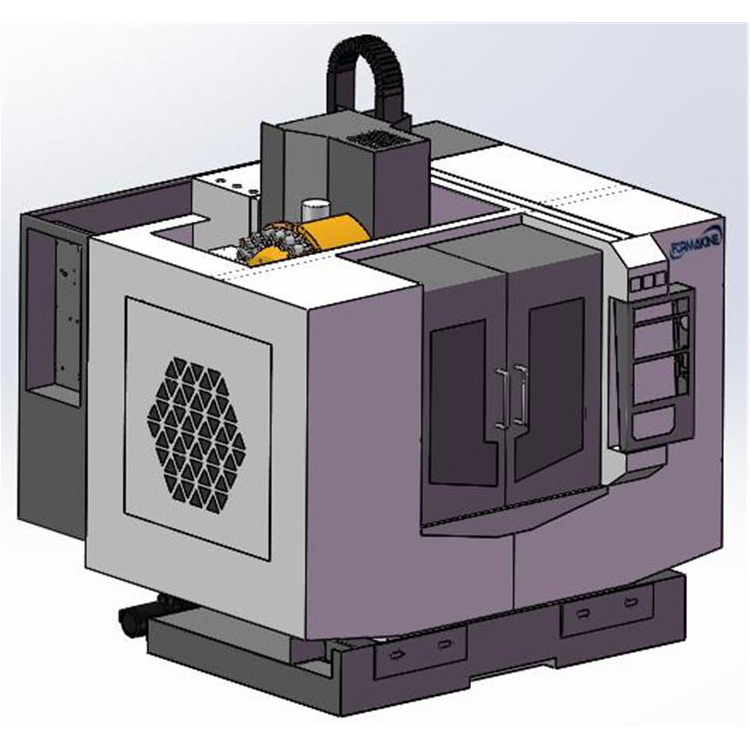

Picture Display

Applications

Power Torque

Workshop

Process

Packing & Shipping