High Precision CNC Hydraulic Guillotine

Product Description

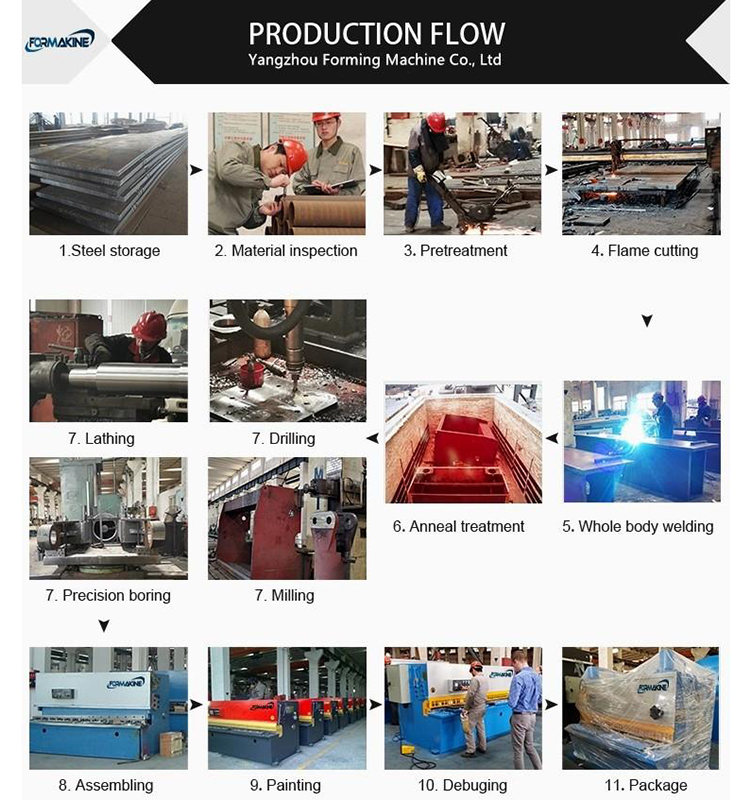

1. Raw materials are purchased from famous company such as AN STEEL. Overall frame welding structure, good rigidity; Anneal treatment to eliminate stress, with perfect stability.

2. The blade's swing running to carry out shearing by hydraulic driving, running in steady.

3. Light alignment device, convenient for line and manual operation;

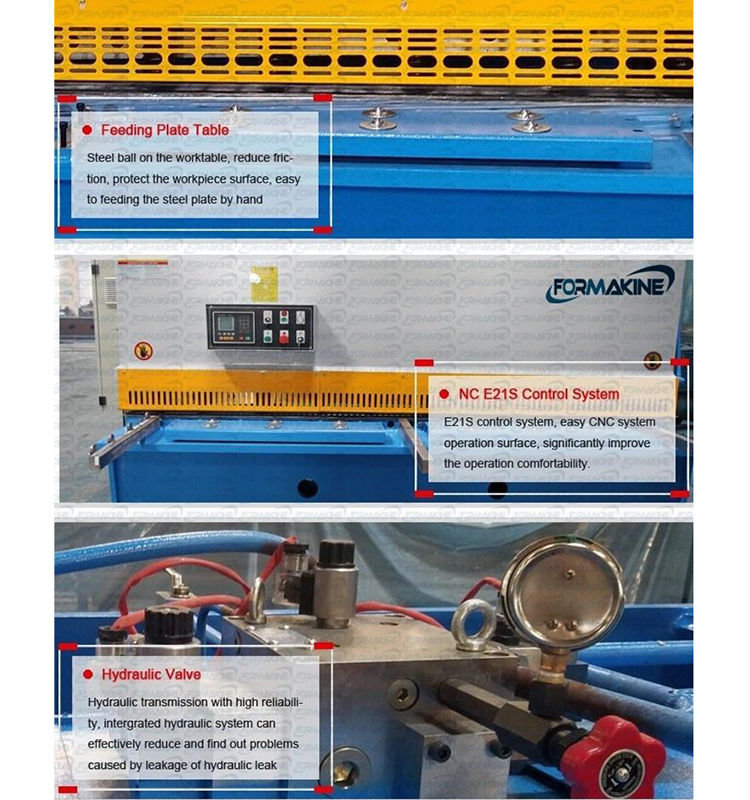

4. Reliable integrated hydraulic system; can effectively reduce problems caused by hydraulic oil leakage.

5. NC control system, back gauge moves fast, numerical display, closed-loop control system, ensures a higher cutting accuracy, CNC system has precision compensation and automatic detection and other additional function;

6. Humanistic concern security design in all details

STANDARD EQUIPMENTS

• Mainly Siemens Electric System, high stability.

• Rexroth or Alpha hydraulic system.

• Siemens motor

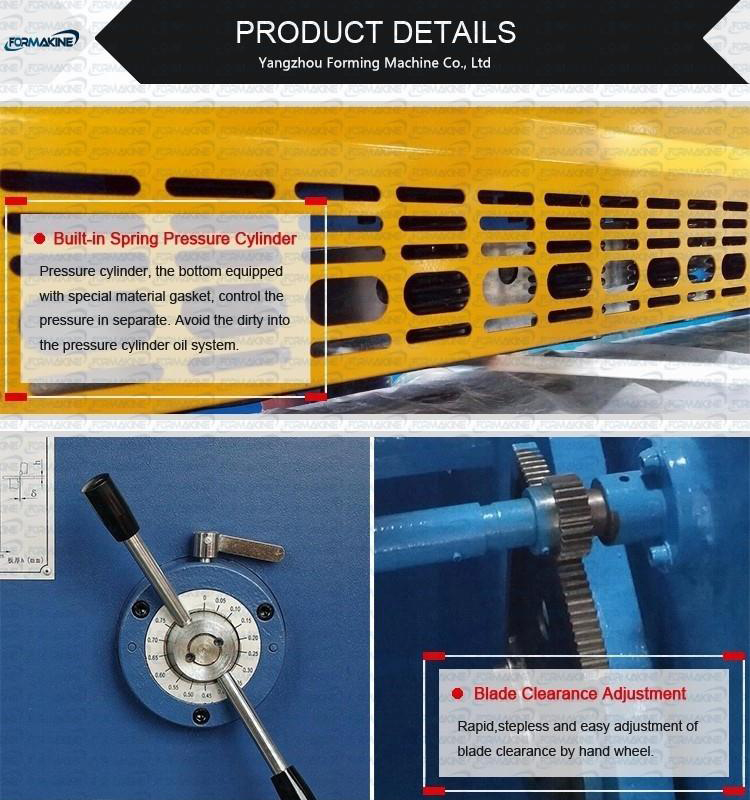

• Hold down cylinders.

• Moveable foot switch.

• Hand wheel to rapidly and accurately adjust the blade clearance.

• Good quality Japanese Valqua seal to prevent leakage of oil

• FILTER in the oil tank.

• Sheet feeding table.

• Hardened blades.

- Top blades: 2 sides

- Bottom blades: 4 sides

• E21S NC controller.

Program memory of up to 40 programs, up to 25 steps per program

Back gauge retract function

One key backup/restore

mm/inch

Chinese/English

• Protective fence which are meet with CE standards, to ensure the operation safety.

• Foldable finger protection guard.

• Emergency stop button.

• 100mm throat depth.

• 20-600mm motorized back gauge with 0.1 mm accuracy.

• 800mm side gauge and front support arms.

• Metric and inch rulers.

OPTIONAL EQUIPMENTS

• bigger throat depth.

• Front angle gauge.

• Side gauge and front support arms in optional lengths.

• Optional back gauge stroke.

• Ball screw with linear guide

• Delem DAC 310 or Estun E200P CNC system

• Motor driven blade gap distance control

• Sheet conveyor and stacking system.

• Sheet support system for thin sheets.

1- Pneumatic support system. (Lever type)

2- Pneumatic support system. (Monobloc panel type)

• REAR DOOR WITH PHOTO-ELECTRIC PROTECTION

• Hydraulic oil cooling and heating system.

• Coolant system or heater can be placed in electric panel during ambient conditions.

• Optional front feeding table.

• Blades special for cutting stainless steel.

• Ability to increase stroke amount per minute.

• Customized colors.

• Double foot pedal.

• Electrical panel or controller can be placed on right side of the machine.

• Central lubrication system.

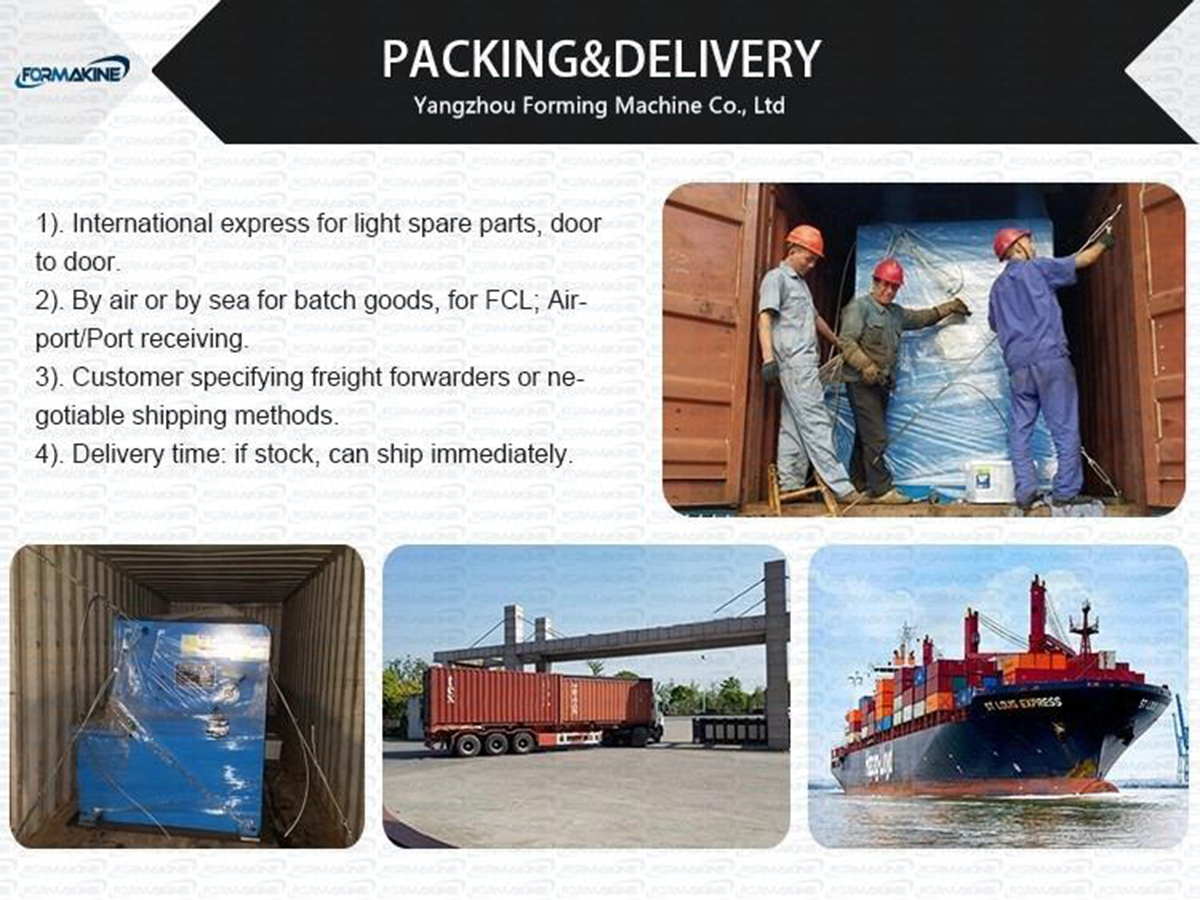

Transportation & Package