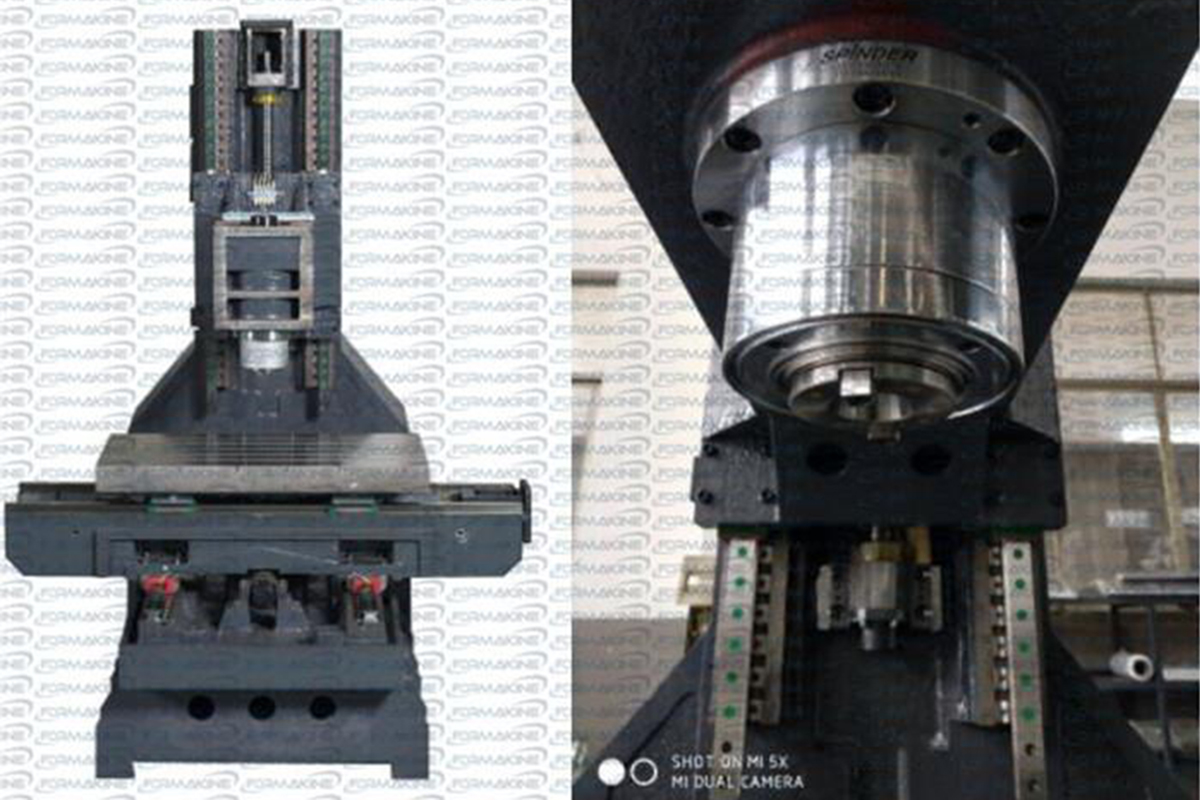

High Performance Vertical Machining Center

Product Description

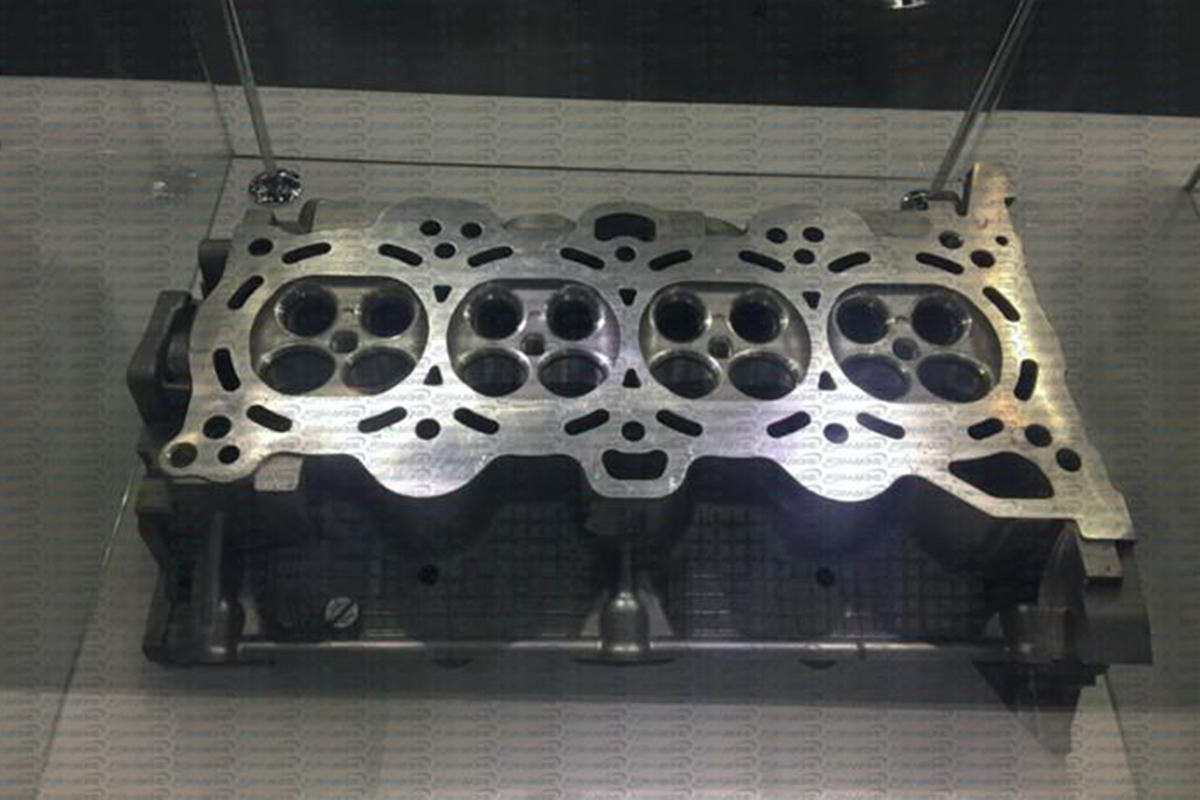

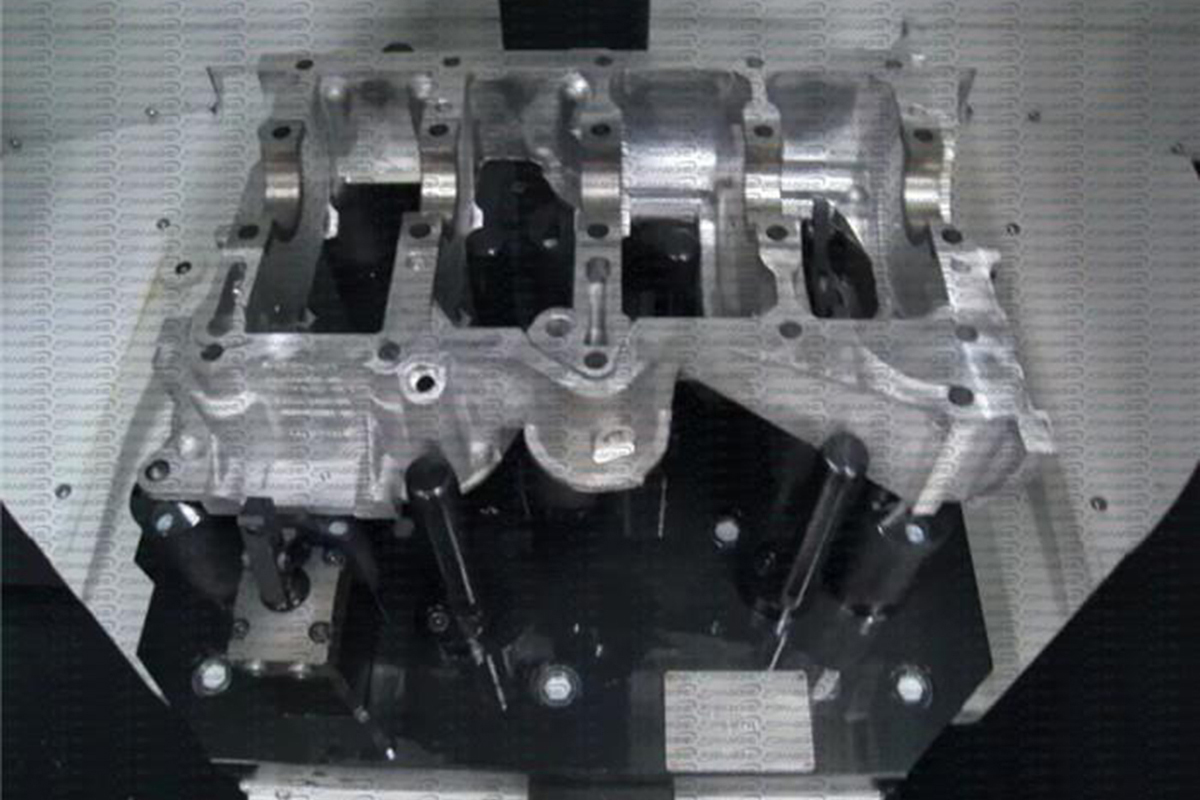

Computer numerical control (CNC) machining centers originated from manually operated milling machines. As both industrial and computer technology has evolved, the machines have become more sophisticated, and are now capable of performing very complex machining tasks.

CNC machining centers may produce actual machined parts or they may be used to cut molds, which are in turn used in producing molded parts. They make use of various types of tools to perform various operations, such as tapping, boring, and drilling, to create the needed part or mold. Machining centers are capable of producing parts within a very tight tolerance, which refers to the parts’standard dimensions and the allowable deviations from the standards.

Technical Parameters

|

SUBJECT |

VMC-855 |

VMC-1160 |

VMC-1370 |

VMC-1580 |

|

Operating Platform |

||||

|

Size Of Operating Platform (Mm) |

1000 * 550 |

1300 * 600 |

1400 * 710 |

1700 * 800 |

|

Specification Of T-Slot |

5 * 18 * 90 |

5 * 18* 100 |

5 * 22 * 120 |

5 * 22 * 135 |

|

Maximun Load |

600kg |

800kg |

1000kg |

1500kg |

|

Distance (Mm) |

||||

|

Maximun Distance Of X, Y And Z Axis |

800/550/550 |

1000/600/600 |

1300/700/600 |

1500/800/680 |

|

Distance Between Spindle And Operating Platform |

120 - 670 |

120 - 720 |

140 - 790 |

160 - 840 |

|

Distance Between Spindle Center And Uprignt Column |

560 |

630 |

770 |

880 |

|

Spindle |

||||

|

Spindle Hole |

BT40 |

BT40 |

BT50 |

BT50 |

|

Maximum Spindle Speed |

10000rpm |

10000rpm |

6000rpm |

6000rpm |

|

Transmission Mode Of Spindle |

Synchronized Belt |

Synchronized Belt |

Synchronized Belt |

Synchronized Belt |

|

Feed |

||||

|

Feed Rate Of Three Axis Cutting |

10000mm/Min |

10000mm/Min |

5000mm/Min |

5000mm/Min |

|

Speed Of Three Axis (M) |

48/48/48/Min |

36/36/36/Min |

18/18/12/Min |

18/18/12/Min |

|

Ball Screw Specification |

4010 |

4010 |

4010 |

5010 |

|

Repeatable Positioning Accuracy |

±0.003/300 |

|||

|

Tool Storage (Selectable) |

||||

|

Tool Capacity |

24 |

|||

|

Maximum Diameter * Length Of Tools (Mm) |

80*200 |

80*200 |

120*300 |

120*300 |

|

Maximum Weight Of Tools |

7kg |

7kg |

15kg |

15kg |

|

Shank Specification |

BT40 |

BT40 |

BT50 |

BT50 |

|

Tool Changing Time |

<2.8s (BT40) |

<4.8s (BT50) |

||

|

Servomotor |

||||

|

Spindle Motor |

7.5/11kw |

11/15kw |

11/15kw |

15/18.5kw |

|

X/Y/Z Axis Motor (Mitsubishi) |

2.0/2.0/3.0kw |

3.0/3.0/3.0kw |

3.0/3.0/3.0kw |

3.0/4.5/3.0kw |

|

Cooling Motor |

0.49kw |

0.49kw |

0.49kw |

0.49kw |

|

General Specification |

||||

|

Power Capacity |

15KVA |

20KVA |

30KVA |

30KVA |

|

Outer Size(Length, Width And Height) |

2.7*2.4*2.5m |

3.2*3.1*2.9m |

3.4*3.3*3.0m |

4.3*3.3*3.0m |

|

Net Weight |

5.5T |

7T |

10.5T |

13.5T |

Workshop

Packing & Shipping