High Efficiency Vertical Machining Center

Product Features

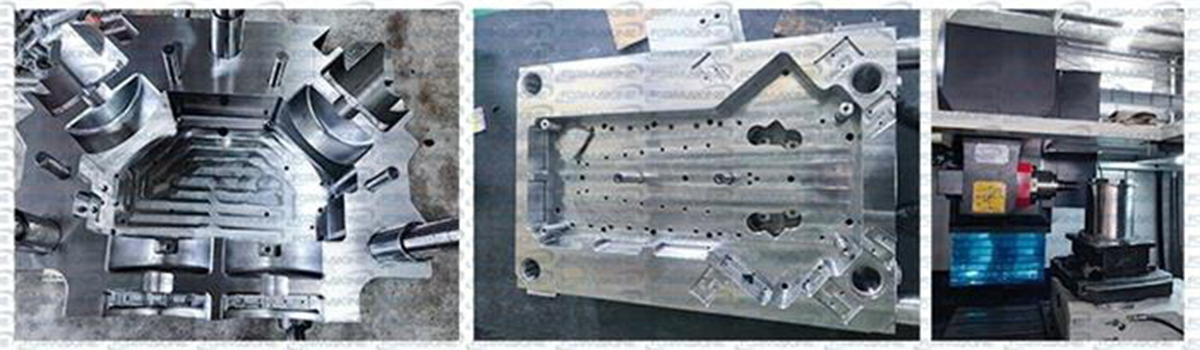

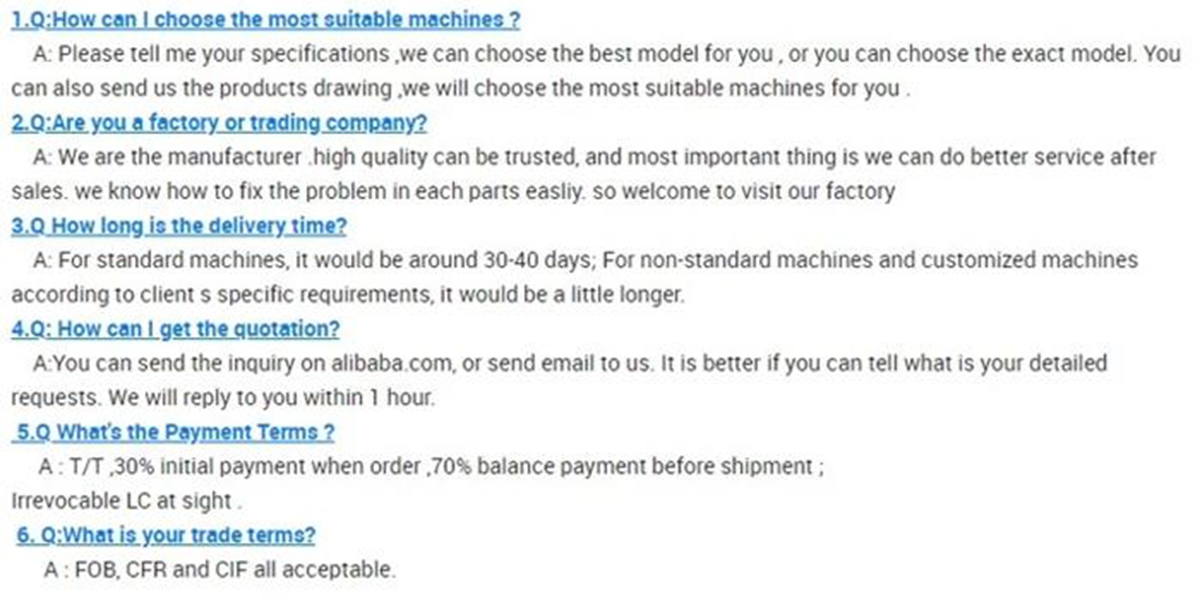

1. High rigidity: the bed-type machining center structure is adopted. The machine tool is composed of base, sliding seat, work table, column and headstock; the main basic parts are analyzed by finite element structure, the structure is reasonable and the rigidity is high; all machine tool castings are Thermal aging treatment, precision has long-term stability.

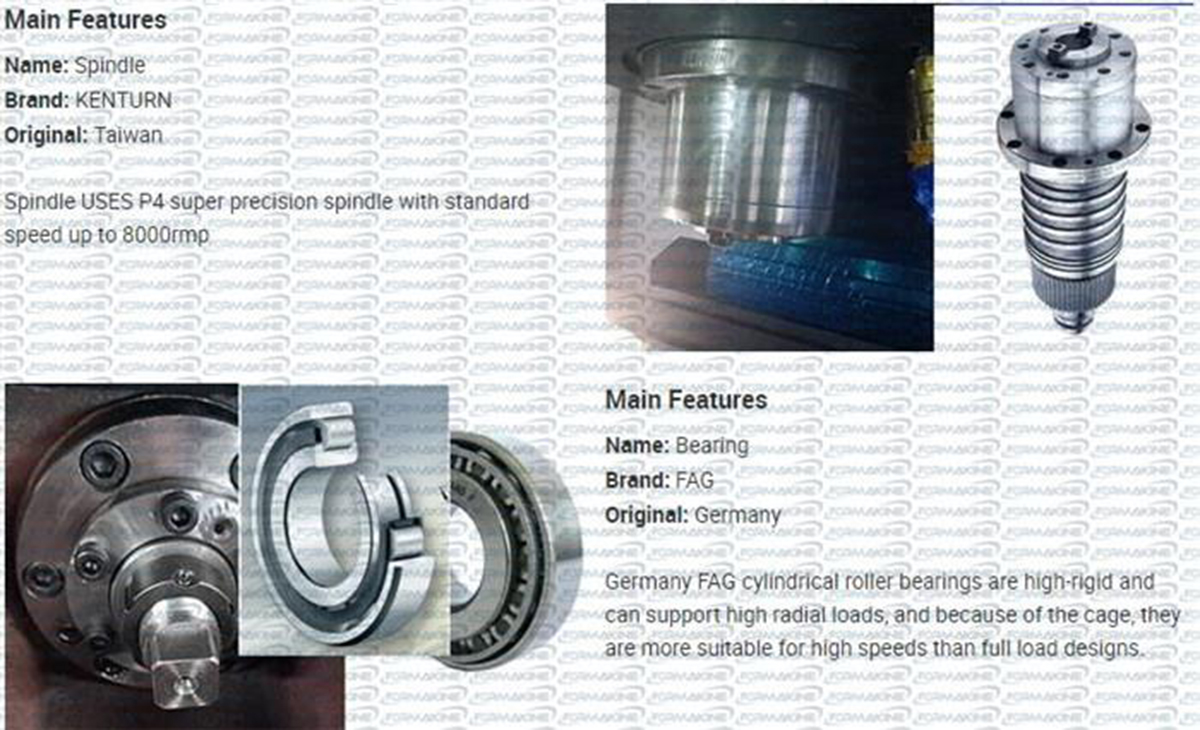

2. The machine tool adopts high-speed, high-precision and high-rigidity spindle unit. The spindle material is made of high-performance alloy steel. The P4 high-speed precision bearing for the spindle is used, and the high-speed grease is used. The spindle speed reaches 8000 rpm and the spindle radial runout is less than 0.006/300.

3. The X, Y and Z direction feed adopts the C3 grade double nut preloaded precision ball screw. The servo motor is directly connected with the lead screw through the high torque and low inertia inlet elastic coupling, and the lead screw support adopts the pretensioning structure. It can eliminate the backlash of the transmission and pre-compensate the influence of thermal deformation on the precision of the machine during long-term operation, ensuring the positioning accuracy and repeat positioning accuracy;

Technical Parameters

|

SPECIFICATIONS |

||

|

Capacity |

Table Size |

135.5/2150 |

|

Max. Table Load |

1060x500mm |

|

|

T Slot Qty-Width*Distance |

600kg |

|

|

Spindle |

Spindle Speed |

8000 Rpm |

|

Spindle Nose To Table Surface |

100-650mm |

|

|

Spindle Center To Column Surface |

575mm |

|

|

Spindle Taper |

BT40-150 |

|

|

Main Motor Power |

7.5kw |

|

|

Three-Axis Servo Motor Power |

2.5/3.0kw |

|

|

Box Way |

X Axis Travel |

800mm |

|

Y Axis Travel |

500mm |

|

|

Z Axis Travel |

550mm |

|

|

X/Y Axis Rapid Feed |

24m/Min |

|

|

Z Axis Rapid Feed |

24m/Min |

|

|

Cutting Feed Speed |

0-6000mm/Min |

|

|

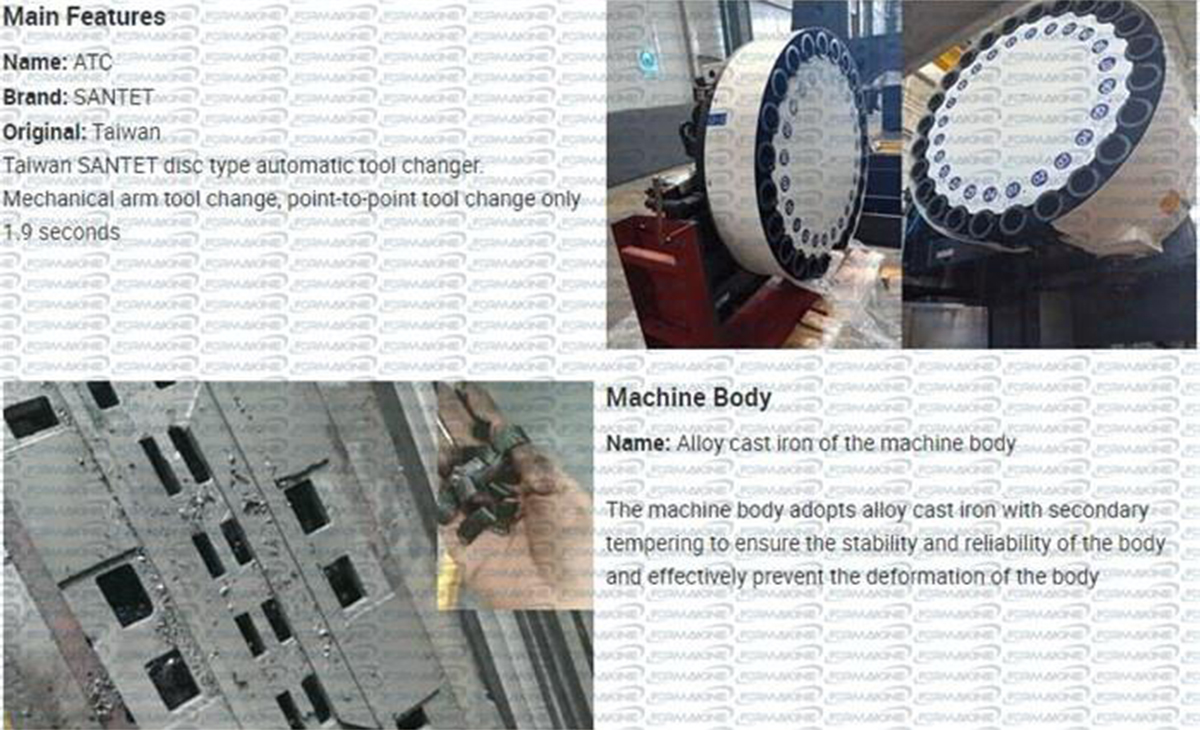

Automatic Tool Changer |

Tool Changer Type |

Disc Type / Hat Type (Arm Type Optional ) |

|

Standard Tool Number |

24pcs |

|

|

Maximum Tool Diameter |

Empty Φ 120/ Full Tool Φ 80 |

|

|

Maximum Tool Length |

300mm |

|

|

Maximum Tool Weight |

7kg |

|

|

Accuracy |

Positioning Accuracy |

300mm/±0.005mm |

|

Accuracy Of Repeated Positioning |

300mm/±0.003 Mm |

|

|

Weight And Size |

Net Weight |

5800 Kg |

|

Overall Dimension |

2950×2100×2600mm |

|

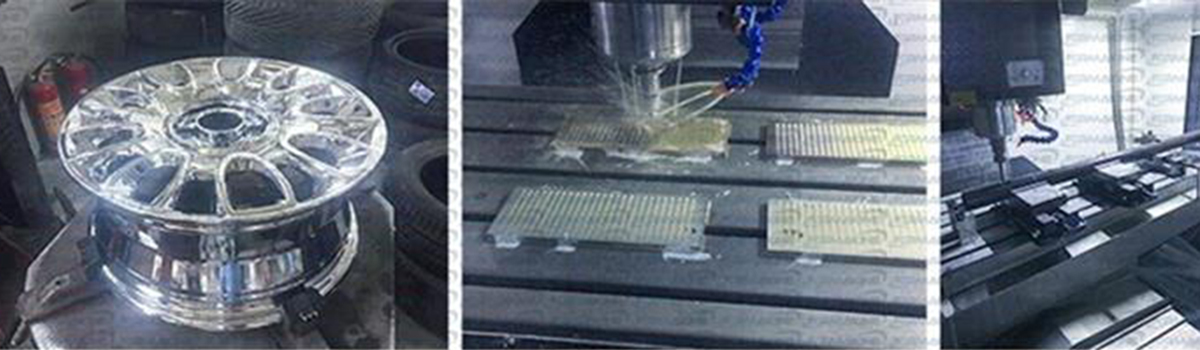

Product Testing

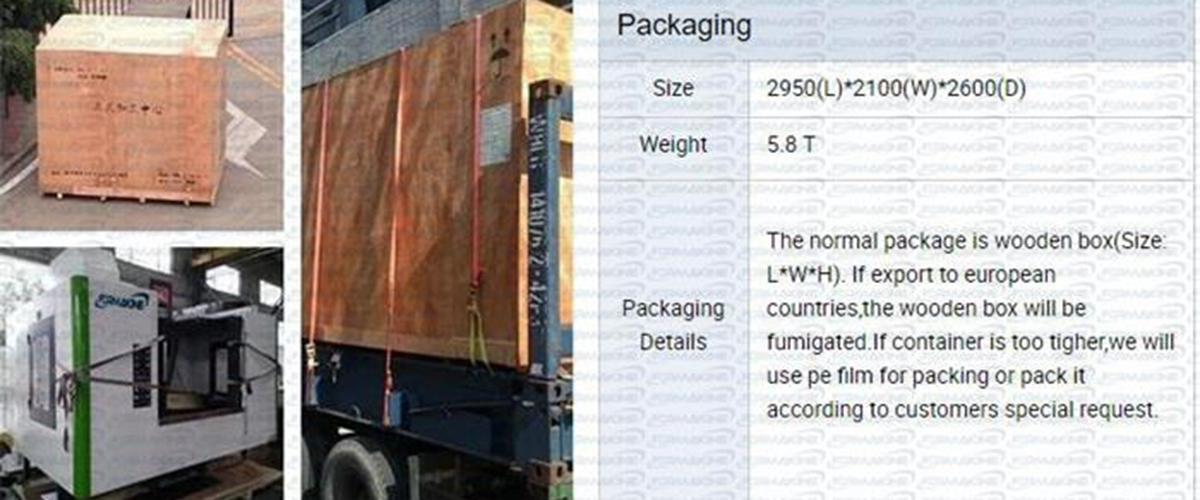

Packing & Delivery