H Frame Single Crank Servo Stamping Press

Product Description

160 Ton Closed Type One Point Servo Stamping Press Machine

Designed For Superior Flexibility And Accuracy

Ideal For Progressive, Transfer Or Manual Die Operations

Incorporates Modern, State Of The Art A.C. Servo Technology Into Mechanical Stamping Press Designs

Ability To Control Slide Velocity And Direction Throughout The Stamping Work Being Done. Optimal Slide Motion Can Be Set For Any Application

Maintains Working Energy Throughout Stroke Regardless Of Slide Velocity

Provides Ability To Dwell At Position To Allow Timing Of Secondary Work Within The Press Production Cycle

Improved Part Quality

Increased Die Life

Ability To Program Multiple Motion Paths Before Returning To Either Top Dead Center Or Programmable Cycle Start Position (Pendulum Mode)

Automatically Maintain And Adjust Slide Position To Assure Either Consistent Die Height Or Load (Tonnage)

Elimination Of High Maintenance Mechanical Components Like The Clutch-Brake Unit And Rotary Union Air Connection

Reduces Die Tryout Time And Expense

Saves Energy Cost By Reducing Electricity Consumption

Technical Specifications

Capacity 1600 KN

Rated Tonnage Point 6mm

Stroke 200mm

Strokes Per Minute 0-60 SPM

Max. Die Set Height 450mm

Slide Adjustment 100mm

Slide Bottom 900x600mm

Bolster1150x800mm

Bolster Thickness 155mm

Max. Allowed Upper Mold Weight: 500KGS

Side Window 560x450mm

Air Pressure 0.5MPa

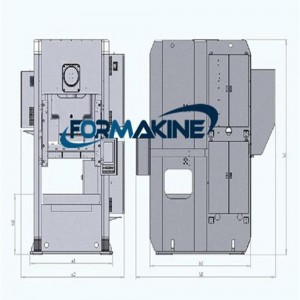

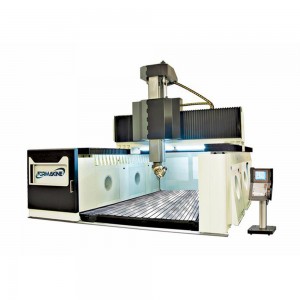

Picture Display

Standard Configuration

The brake device

Servo motor slide adjustment

Die height digital display

Hydraulic overload protector

Electromagnetic slide locking device

Balance cylinder

Forced circulation oil feeding device

Balance cylinder oil supply device(Manual)

Air ejector

Air outlet

Air controller and pressure gauge

Servo synchronous motor

Optional Equipment

Manual safety shield door

Quick die change system

Die cushion

Material oiling device

Thermal deformation control

Lighting for operation

Mold protecting system

Fault detection device