Front Feeding Hydraulic Guillotine Shearing Machine

Product Features

Complete machine includes CNC Guillotine Shear Machine and CNC controled Front feeding unit;

CNC feeding unit is driven by high efficient ball screw and linear guide; servo motor Directly drive;

Pneumatic clamps will hold the sheet metal and move accurately according CNC shearing machine controller’s program;

CNC Guillotine Shear Machine plus CNC feeding will realize one time plate install and automatic finish sheet cutting function. It will efficiently reduce human operation. Plate cutting accurate is high.

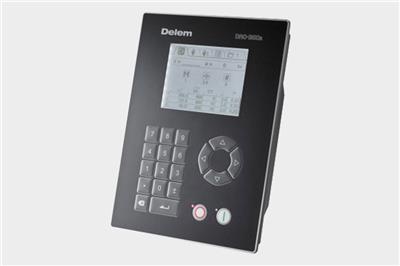

CNC controller can be DELEM DAC310, DAC360, ESTUN E21, DTC660 professional for CNC Guillotine Shear Machine;

CNC Guillotine Shear Machine’s hydraulic cylinder is connected in series. cutting angle is adjustable. smaller cutting angle can reduce sheet edge twist. bigger cutting angle can cut big thickness;

Both UP and down blades of CNC Guillotine Shear Machine have 4-cutting edge; blades life is longer;

Shearing blades material can be 6CrW2Si for mild steel or H13 / 12CrMoV for harder sheet metal;

Front feeding CNC Guillotine Shear Machine has no back gauge.

CNC controller can control front gauge, shearing rake angle, cutting length;

Rear side of CNC Guillotine Shear Machine can be optional equipped with pneumatic following support. It means during cutting, the rear support will follow sheet cutting.

Product Introduction

Front Feeding Device

Since the structure advantage of the plate guillotine shearing machine, FORMAKINE stops producing swing beam plate but to choose NC guillotine plate shear as basic shearing machine type. Stability, speed and precision are most important factors of an excellent sheet metal shear, and FORMAKINE NC guillotine plate shear will brings you amazing shearing experience.

Hydraulic System

According to the width and the thickness to be cut, a manual and very simple device allows for a fast and precise adjustment of the gap between the blades. The manual wheel on the front of the machine enables the Adjustment in tenths of a millimeter of the blades according to the thickness to be cut.

Shearing Angle controlled by the ESTUN E21S NC control system. The adjustable shearing angle reduces the distortion of plate material.

Electrical Carbinet

A LED light produces a slender shadow on the cutting path, easy to locate the cutting line when operators need to align the cutting position.

Technical Parameters

|

Item |

QC11K-6X2500/2500 |

QC11K-6X3200/3000 |

|

Max Shearing Thickness (Mm) |

6 |

6 |

|

Shearing Length(Mm) |

2500 |

3200 |

|

Plate Material Strength(Mpa) |

450 |

450 |

|

Shearing Angle(Degree) |

0.5~2 |

0.5~2 |

|

Shearing Times Per Min( /Min) |

12 |

9 |

|

Volume Of Oil Tank (L) |

275 |

300 |

|

Main Power(Kw) |

7.5 |

7.5 |

|

CNC FEEDING UNIT |

|

|

|

Max Stroke (Mm) |

2500 |

3000 |

|

Positioning Accuracy (Mm) |

+/-0.1/300 |

+/-0.1/300 |

|

Clamp Numbers |

5 |

7 |

|

Compressed Air (Mpa) |

0.6 |

0.6 |

|

Overall Dimension LxWxH (Mm) |

4990x3290x1730 |

5650x4000x1730 |