Eccentric Gear Straight Side Stamping Press

Product Description

2000 Tos Four Points Eccentric Gear Straight Side Press Machine

Four points eccentric gear press machine is of high universality in processing including blanking, forming, bending, shallow-drawing, cold forming etc. it is especially suitable for pressing various thin sheet forming parts. This series is widely used in industries including automobile, tractor, agriculture machinery, textile machinery, electrics, motor, instrument, aviation and weapons, etc, can be equipped with various kinds of movable bolster with PLC control.

. Optimized design for drive system and appearance by Solidwork

. Specialized dry type clutch and brake

. Four pieces suspensions

Welded Type Gears With Higher Bending Stress

Both the middle gear and the side eccentric gear are welded type. The gear ring material is high strength alloy steel. Heat treatment after welding. This design is much better than conventional type casting steel type gear. All gear teeth surfaces are grinded and the transmission efficiency could be bigger than 95%. All conform to JIS-2 standard.

Standard Configuration With Front Side Movable Working Table

All the four points eccentric gear press machines are standard configured with front side movable bolster. There are positioning pins in the bolster and the repeat positioning accuracy could achieve 0.05mm. The lifting and clamping of the working table are both carried out through hydraulic cylinders. Standard configured with rails cleaning fingers and monitor sensor for dirty.

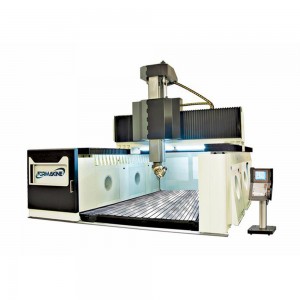

Picture Display

Technical Specifications

| Specifications (Four Points Eccentric Gear Press) | Unit | 630 Ton | 1000 Ton | 1250 Ton | 1600 Ton | |

| Nominal Force | KN | 6300 | 10000 | 12500 | 16000 | |

| Nominal Stroke | Mm | 13 | 13 | 13 | 13 | |

| Slide Stroke | Mm | 600 | 800 | 800 | 700 | |

| Slide Strokes Per Minute | Min-1 | 9-14 | 9-14 | 8-12 | 8-12 | |

| Maximum Die Set Height | Mm | 1300 | 1400 | 1400 | 1400 | |

| Die Height Adjustment | Mm | 500 | 600 | 600 | 600 | |

| Bolster Size | A | Mm | 3500x2000 | 3800x2200 | 3800x2200 | 4200x2400 |

| B | Mm | 4000x2000 | 4500x2400 | 4500x2400 | 4800x2400 | |

| C | Mm | 4500x2200 | 5000x2500 | 5500x2500 | 5500x2500 | |

| Bottom Size Of Slide | A | Mm | 3500x2000 | 3800x2200 | 3800x2200 | 4200x2400 |

| B | Mm | 4000x2000 | 4500x2400 | 4500x2400 | 4800x2400 | |

| C | Mm | 4500x2200 | 5000x2500 | 5500x2500 | 5500x2500 | |

| Distance Between Plane And Ground | Mm | 700 | 750 | 750 | 750 | |

| Cushion | Pressing/Ejector Force | KN | 1000 | 1500 | 2000 | 2500 |

| Stroke | Mm | 0-300 | 0-300 | 0-300 | 0-300 | |

| Movable Working Table | Quantity | 1 | 1 | 1 | 1 | |

| Loading Bearing | T | 25 | 35 | 40 | 50 | |

| Motor Power | KW | 75 | 132 | 160 | 200 | |

| Height Press Above Ground | Mm | 9100 | 9600 | 9800 | 10500 | |