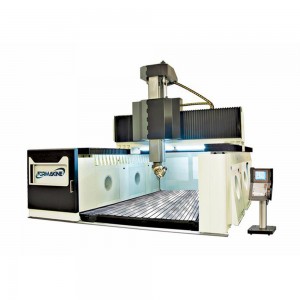

CNC Vertical Machining Center

Product Description

* Machining Center body is optimized design by computer CAD/CAM, with the structure of wide body and column.Casting by the quality Meehanite resin sand process. Times effect of aging treatment times,

* The adoption of C3 grade precise ball screws and the use of special bearing on the ball screw with pre-pull treatment as well as laser detective compensation have ensured the rigidity and precision.

* The adoption of balance weight block with motion-based device has prevented the spindle form vibration when weight-balanced block moves up and down, avoiding influencing the processing accuracy.

* The main base parts of Vertical Machining Center are made from high-grade ,high quality gray casting iron with aging treatment, the guide rails with high-frequency quenching treatment and delicate grinding ,covered with low frictional coefficient TURCITE-B and dealt with delicate scraping ,having effectively improved motional quality of machine and necessary touching rigidity for cutting.

Characteristics

1.Machine bed:

Machine bed is made by the advanced resin sand casting material, internal stress eliminated by special method. With the exquisite design, the bed has the excellent performance for machining and accuracy requirements.

2.Transmission Shaft:

Machine adopt the box way guide, made by the advanced resin sand casting material, load ability improved greatly;

3.Lead Screw:

High accuracy and high quality ball screw is adopted to make sure the positional accuracy;

4.Spindle Motor:

High quality motor make sure that the lathe perform well at high or low speed and light or heavy cutting(11/15Kw);

5.Electrical Cabinet:

Heat exchanger is installed in electricity cabinet to guarantee the stable of system. Coiler is equipped out side, it is heat, oil and water-resistant;

6.Lubrication System:

Automatic Centralized Lubrication System can provide timely and accuracy lubrication according to the lathe situation to make sure the machine can work continuously;

7.Advanced FANUC/Mitsubishi Controller.

Product Features

1. T-shaped base structure, which can withstand stronger dynamic load.

2. Widened column, with better rigidity.

3. Workpiece move on Y axis which connects with base, which makes machine have stronger dynamic load.

4. Saddle and headstock are mounted on column, the X/Z axis withstand stable force.

5. Headstock is compact. Direct-driven and motirized spindle can be installed. Spindle reduction gearbox can be installed too.

6. Roller type linear guide rails are adopted for 3 axes, which has a great performance during heavy duty machining. Rapid traverse of 3 axes is 30m/min.

Technical Parameters

| Specification | Metric | Inch |

| Worktable | ||

| Table Size | 1050 X 500 M M | 41 X 20 In |

| T-Slot Size | 5 X 18 X 90 Mm | 5 X 0.7 X 3.5 In |

| Max. Loading Capacity | 1000 Kg | 2205 Lb |

| Travel | ||

| X/Y/Z Axis Max. Travel | 800/500/500 Mm | 31/20/20 In |

| Spindle Nose To Worktable | 150-650 Mm | 6-26 In |

| Spindle Center To Column Surface | 550 Mm | 22 In |

| Spindle | ||

| Spindle Taper | BT40 | BT40 |

| Max. Spindle Speed | 8000 Rpm | 8000 Rpm |

| Spindle Drive | Belt Drive | Belt Drive |

| Feeding | ||

| X/Y/Z Axis Cutting Speed | 10000 M/Min | 394 In/Min |

| X/Y/Z Axis Rapid Travel | 30/30/30 M/Min | 1181/1181/1181 In/Min |

| ATC | ||

| Tool Capacity | 24 | 24 |

| Max. Tool Dia. | Φ80 | Φ3 |

| Max. Tool Length | 200 Mm | 8 In |

| Max. Tool Weight | 7 Kg | 15 Lb |

| Servo Motor | ||

| Spindle Motor | 7.5/11 Kw | 10/15 Hp |

| X/Y/Z Axis Motor (Mitsubishi) | 2.0/2.0/2.0 | 2.7/2.7/2.7 Hp |

| X/Y/Z Axis Motor (Fanuc) | 1.8/1.8/1.8 Kw | 2.4/2.4/2.4 Hp |

| Coolant Motor | 0.49 Kw | 0.66 Hp |

| General Spec. | ||

| Air Required | 6 Kg/Cm2 | 85 Psi |

| Dimension(L X W X H) | 2700 X 2400 X 2500 M | 106 X 94 X 98 In |

| Net Weight | 7500 Kg | 16535 Lb |

Main Configuration

| Standard Configuration:FANUC/Mitsubishi Control

Heat Exchanger For Electric Cabinet Standard RS-232 Interface & RS-232 Cable Z Axis Nitrogen Cylinder Fully Enclosed Enclosure Automatic Centralized Lubrication System Hydraulic System Rigid Tapping MPG Control Working Light Working Status Indicating Light 3 Phase Isolate Transformer Toolkits Leveling Screws And Pads Operations Manual |

Optional Configuration:GSK Control

Arm Type A.T.C. 24 Tools Rotary Table (Fourth, Fifth Axis) Chip Conveyor And Chip Bucket Spindle Oil Chiller Oil Mist Filter Automatic Voltage Regulator

|

Picture Display

Production Process

Customers

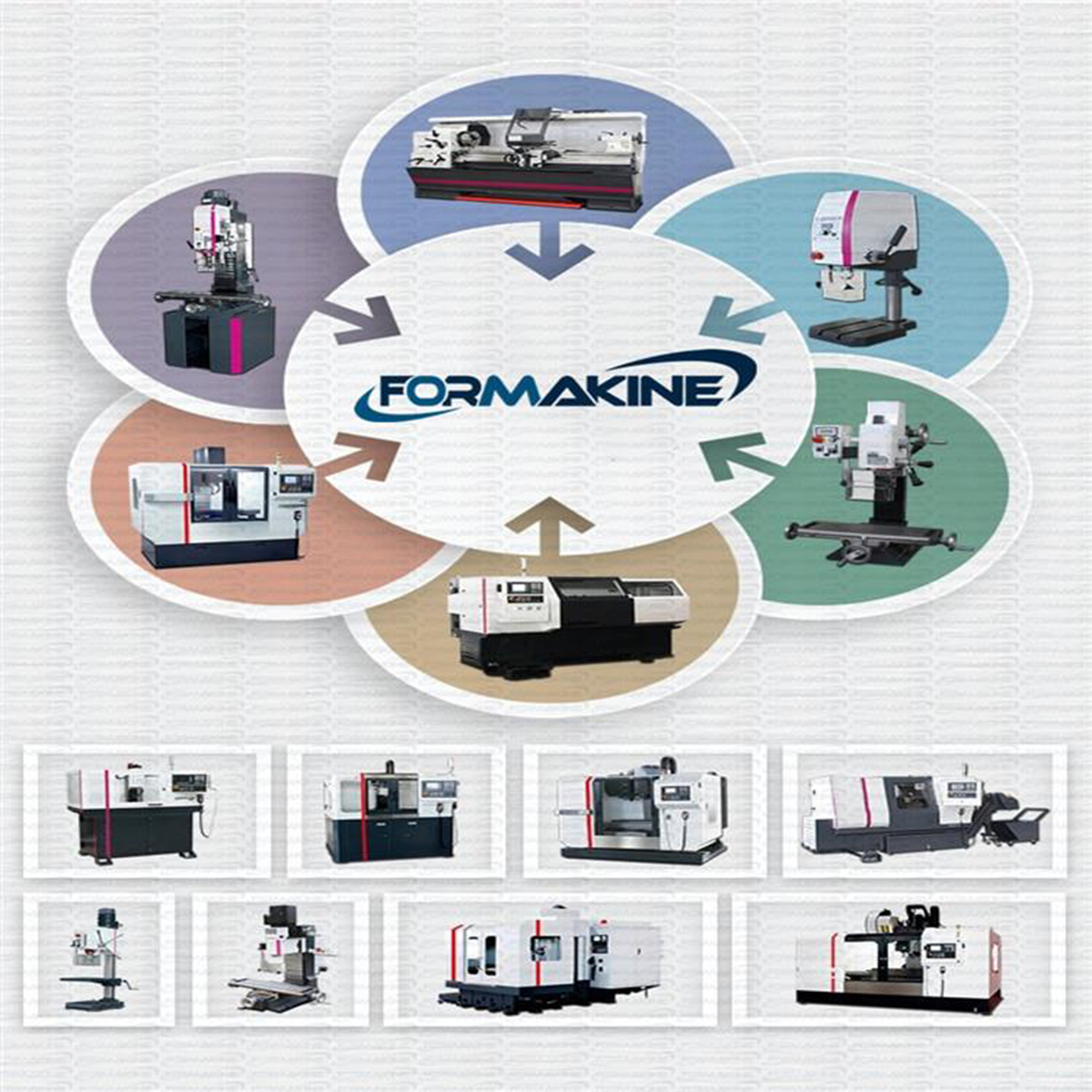

Products Range

Research & Development

Applications

Packing & Transportation