CNC Round Pipe Bending Machine

Product Description

CNC Round Pipe Bending Machine

Full-automatic pipe bending machine equipped with PLC or IPC which manage Bending (Y), Feeding (B) & Rotation (C) in a complete automatic cycle.

Ranging from 10mm up to 220mm OD these machines are suited for use in a wide range of pipe manufacturing sectors and industries. Available in different versions, there's all three axis are automatic in a single stack machine.There’s also the option to add push bending function, left and right bending function, more stacks,and so on.

The series comes equipped with easy-to-operate touchscreen controls, or with the latest user-friendly 3D bending software. This stores tooling configuration, allows spring-back compensation, and boasts anti-collision technology, amongst other features.

Feature

* Interactive PLC touch screen offers easy access to auto and manual operating modes.

* System diagnostics and multiple language capability.

* Fully hydraulic clamping on clamp die and pressure die.

* Bending (Y-Axis): Controlled by Servomotor or by Hydraulic.

* Feeding (B-Axis): Controlled by Servomotor.

* Rotating (C-Axis): Controlled by Servomotor.

* Equipped with adjustable speed valve on pressure die ensures the synchronization of bending.

* Air cooling system ensures the equipment long-time work stably under the high temperature.

* CE&ISO 9001:2000.

Technical Parameters

| Model | 38CNC-2A-1S | 50CNC-2A-1S | 63CNC-2A-1S | 76CNC-2A-1S |

| Max Capacity | ¢38.1 (1.5”)×2mm | ¢50.8 (2”)×2mm | ¢63.5 (2.5”)×4mm | ¢76.2 (3”)×5mm |

| Bending Degree | 0-190° | 0-190° | 0-190° | 0-190° |

| Bending Radius | 10-200mm (For Machine) | 15-250mm (For Machine) | 20-300mm (For Machine) | 25-350mm (For Machine) |

| Min Bending Radius | R≥1.5D (For Pipe) | R≥1.5D (For Pipe) | R≥1.5D (For Pipe) | R≥1.5D (For Pipe) |

| Mandrel Length | 2300mm (Can Be Customized) | 2500mm(Can Be Customized) | 3000mm(Can Be Customized) | 3200mm(Can Be Customized) |

| Max Bending Speed | 90°/S | 65°/S | 60°/S | 45°/S |

| Bending Accuracy | ±0.1° | ±0.1° | ±0.1° | ±0.1° |

| Motor Power | 4 Kw | 5.5 Kw | 7.5 Kw | 7.5 Kw |

| Model | 89CNC-2A-1S | 114CNC-2A-1S | 129CNC-2A-1S | 168CNC-2A-1S |

| Max Capcity | ¢89 (3.5”)×8mm | ¢114 (4.5”)×8mm | ¢129(5”)×12mm | ¢168(6.5”)×16mm |

| Bending Degree | 0-190° | 0-190° | 0-190° | 0-190° |

| Bending Radius | 30-450mm (For Machine) | 40-550mm (For Machine) | 50-650mm (For Machine) | 60-850mm (For Machine) |

| Mini Bending Radius | R≥1.5D (For Pipe) | R≥1.5D (For Pipe) | R≥1.5D (For Pipe) | R≥1.5D (For Pipe) |

| Mandrel Length | 3800mm(Can Be Customized) | 4500mm(Can Be Customized) | 4600mm(Can Be Customized) | 6500mm(Can Be Customized) |

| Max Bending Speed | 40°/S | 25°/S | 20°/S | 10°/S |

| Bending Accuracy | ±0.1° | ±0.1° | ±0.1° | ±0.1° |

| Motor Power | 11 Kw | 15 Kw | 18.5 Kw | 22 Kw |

Options

* IPC Controlling

* Double/Triple/Quadruple Stack (Different Radius on one pipe bending)

* Pipe Push Bending Function(Big Radius)

* Extra Mandrel Length

* Left&Right Head Bending

Pipe Bending Macine Push Bending

For Large Radius (Optional)

Pipe bending Macine Push bending for large radius (Optional)

Tube bending Machine multi-layer type (Optional)

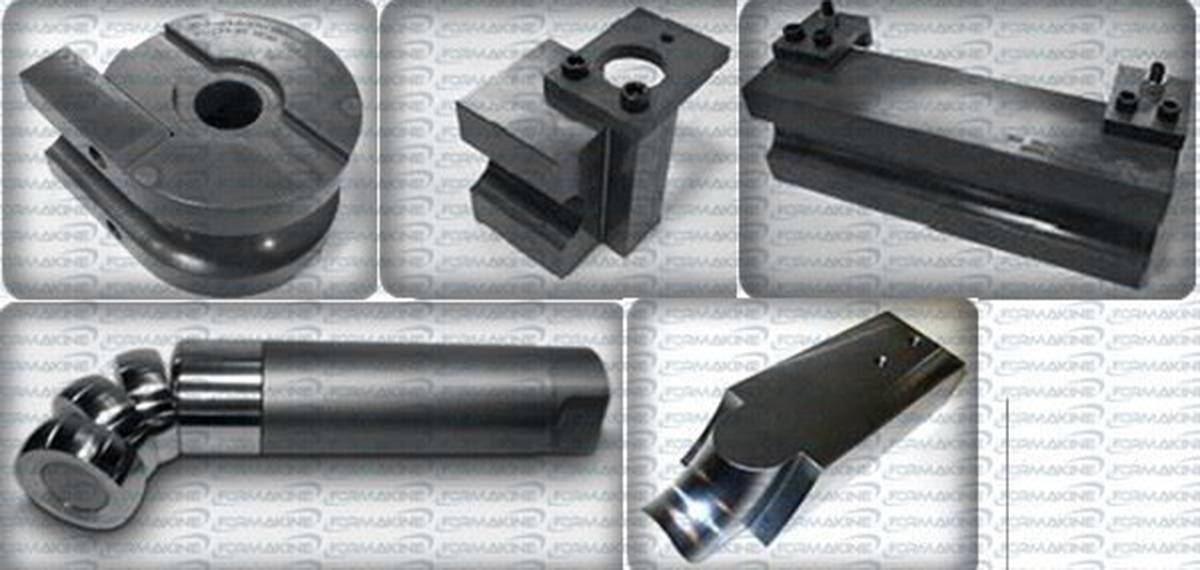

Tool & Accessories

STANDARD MATERIAL: 45# STEEL

Optional Materials:

* Ampco Bronze- Mandrel&Wiper die for Stainless Steel Pipe

* Nylon- Bending die,Clampe die&Pressure die for Aluminum Pipe

* Cr 12-For other pipe material

Related Products

Logistics