Carbon Steel Plasma Cutting Machine

Product Description

Plasma cutting machine has been widely used for outer frame processing of electro-mechanical products ,advertising signs , decoration , garden iron art , vehicle manufacturing ,ship building , electric appliances , metal plate material cutting and other industries

Application materials : stainless steel , mild steel , brass , copper , aluminum alloy , metal sheet , spring steel , gold , sliver etc

Application industry : Sheet metal , Kitchenware , components , decorations industry.

Product Features

(1).It is for metal precise cutting powered by fiber laser technology.

(2).The quality fiber laser beam results in faster cutting speeds, higher quality cuts compared to other cutting solutions.

(3).The key advantage of a fiber laser is its short beam wavelength . The wavelength, which is ten times lower than that of C02 laser, generates high absorption into metals.makes it become a perfect tool for cutting metal sheets of stainless steel, carbon steel, mild steel, aluminum, brass, etc.

Technical Specifications

|

Carbon Steel Plasma Cutting Machine |

|

|

Power |

2000W |

|

Cutting Area(L*W) |

3000mm*1500mm |

|

Cutting Thickness |

0.2mm-16mm |

|

Total Electric Power Consumed |

15kw/H |

|

Laser Cutter Cutting Speed |

According To The Thickness |

|

X Axis Route |

3050mm |

|

Y Axis Route |

1525mm |

|

Z Axis Route |

120mm |

|

X, Y Axis Orientation Precision |

±0.03mm/M |

|

X/Y Axis Repeat Precision |

±0.02mm/M |

|

Maximum Positioning Speed |

80m/Min |

|

Worktable Max Load |

1200kg |

|

Weight Of The Machine |

8000kg |

|

CNC System |

Baichu Or Customized |

|

Laser |

RAYCUS/IPG Laser |

|

Reducer |

Germany Newcut |

|

Rack And Pinion |

Taiwan YYC |

|

Linear Guides |

Taiwan PMI |

|

Cooling System |

Water Cooling |

|

Laser Cutting Head |

American Lasermech |

|

Appliances |

France Schneider |

|

Servo Motor |

Matsushita |

|

Dimension(L*W*H) |

5000x2500x1800 Mm |

Picture Display

Production Equipment

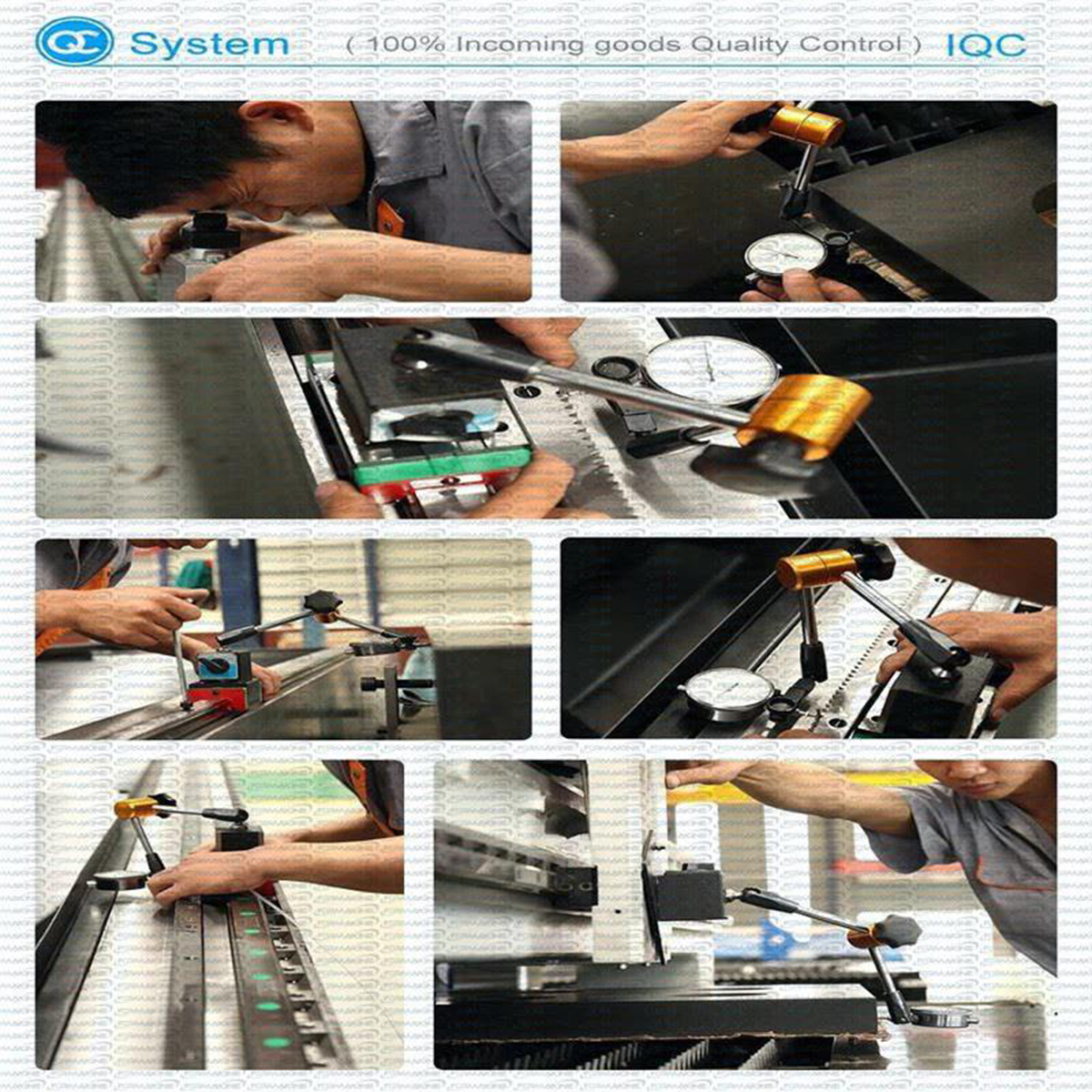

System

Samples

Advantage

1) Excellent Beam Quality: the focused spot smaller cut lines more sophisticated, higher productivity, better quality and p

rocessing;

2) A High Cutting Speed: is the same power CO2 laser cutting machine 2 times;

3) High Stability: The world's top imported fiber laser, stable performance, a key component of up to 100,000 hours lifetime;

4) High Electro-Optical Conversion Efficiency: fiber laser cutting machine than the CO2 laser Electrical and optical conversion efficiency is three times higher, energy savin

g and environmental protection;

5) Low Cost: cutting machine consumes only 20-30% of similar CO2 laser;

6) Very Low Maintenance Costs: no laser working gas; optical fiber transmission, without reflecting lenses; can save a lot of

maintenance costs.

Workshop

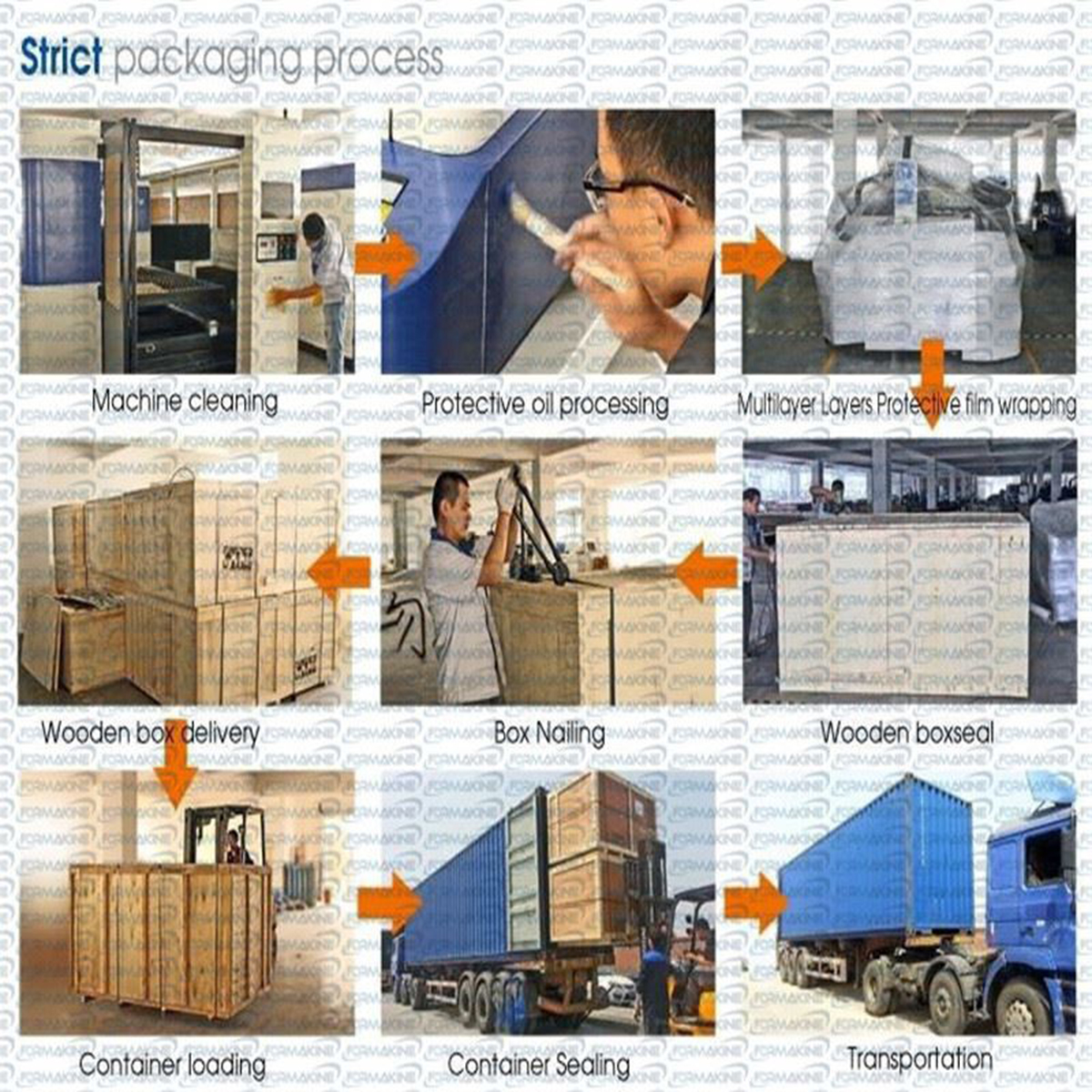

Packing & Delivery