C Frame Single Crank Adjustable Stroke Press

Product Features

JL21-100 C Frame Press Machine With Adjustable Stroke

APA Type Press Machine

With High rigidity rack design, they are welded with the use of high-quality steel plates, through releasing of internal stresses,so that stability and reliability of the whole machine accuracy can be enhanced.

Consistent driving center and machine center to guarantee accurate and stable punching

In order to guarantee relative stationarity of machine operation, it is necessary to balance two balances.

Moulding-adjustment precision is as high as 0.1mm, safe,speedy ,and reliable.

Through hard oxidation and grinding ,such parts as bent axles,gear sets,and connecting rods possess higher combination property and tolerance.

Adopt highly sensitive and reliable clutch/brake and internationally top duplex,to guarantee precision and safety for operation and stop of press rams/slides.

Machine's structural design shall be reasonable,for the convenience of realizing automatic production,reducing cost,and improving efficiency.

Possess advanced design concepts, low noise, low consumption,and energy saving.

Technical Specifications

| Serial Number | Names | Unit | Specifications | |

| JL21-160A | JL21-200 | |||

| 1 | Nominal Capacity | KN | 1600 | 2000 |

| 2 | Nominal Capacity Stroke | Mm | 6 | 7 |

| 3 | Stroke Of Slide | Mm | 16.5-160 | 18.7-180 |

| 4 | Strokes | SPM | 35-55 | 30-50 |

| 5 | Max. Permissible EngagingNumber Of Clutch In Intermittent Strokes(Per Minute) | SPM | 24 | 24 |

| 6 | Max. Die Set Height | Mm | 460 | 480 |

| 7 | Die Height Adjustment | Mm | 100 | 110 |

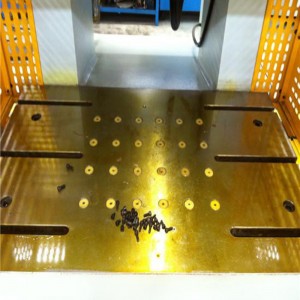

| 8 | Size Of Table(FB X LR) | Mm | 650X1200 | 800X1350 |

| 9 | Thickness Of Table | Mm | 180 | 200 |

| 10 | Size Of Opening In Table | Mm | Φ160 | Φ180 |

| 11 | Bottom Size Of Slide (FB X LR) | Mm | 450X760 | 570X900 |

| 12 | Hole For Punch Shank (Diameter XDepth) | Mm | Φ70X80 | Φ70X80 |

| 13 | Distance Between Uprights | Mm | 690 | 820 |

| 14 | Overalldimensions (LRx FBx H) | Mm | 1410X1900X3550 | 1500X2650X3950 |

| 15 | Main Motor(Power) | KW | 15 | 22 |

| 16 | Air Pressure | MPa | 0.5 | 0.5 |

| 17 | Total Weight (Approximately) | Kg | 14300 | 21000 |

Press Machine Slide Adjustable Stroke (8 Steps Adjustable Stroke)

| JL21 | JL21-16 | JL21-25 | JL21-45 | JL21-63 | JL21-100 | JL21-160 | JL21-200 | JL21-250 |

| 1 | 8.3 | 10.4 | 11.5 | 12.5 | 14.6 | 16.6 | 18.7 | 22.9 |

| 2 | 24.7 | 30.9 | 34 | 37.1 | 43.3 | 49.5 | 55.6 | 68 |

| 3 | 40 | 50 | 55 | 60 | 70 | 80 | 90 | 110 |

| 4 | 53.5 | 67 | 73.7 | 80.4 | 93.8 | 107.2 | 120.6 | 147.4 |

| 5 | 64.7 | 80.9 | 89 | 97 | 113.3 | 129.4 | 145.6 | 178 |

| 6 | 73 | 91.3 | 100.4 | 109.6 | 127.8 | 146 | 164.3 | 200.9 |

| 7 | 78 | 97.8 | 107.6 | 117.4 | 136.9 | 156.5 | 176 | 215 |

| 8 | 80 | 100 | 110 | 120 | 140 | 160 | 180 | 220 |

Configuration

Optional Configuration

Optional Configuration

>Inverter

>Hydraulic over-load protector

>Slide manual adjust(60 Tons and below)

>Slide eletric/motorized adjust device(80 tons and above)

>Die height mechanical indicator(60 Tons and below)

>Die height eletric indicator(60 Tons and above)

>Balance device

>Rotary cam switch

>Misfeed detection consent

>Power supply

>Crank angle indicator

>Electrical stroke counter

>Air source connector

>Against over-run safety device

>Air ejector

>Maintenance tool box

>Pperation manual

>High perfoamance wet clutch & brake(OMPI Dry clutch & brake also available)

>Eletrical automatic lubrication system

>Pneumatic die cushion device

>Foot switch

>Quick die change device(die lifter,clamp and die moving arms )

>Slide knock-out device

>Auti-vibration press mount

>Photo-electronic safety device

>Die room light

>Touch pad(preset, total counter)

>PAC 100 counter system

>Human-computer counter system

Press Machine Regular Check

Inspection before operating and daily inspection

The regular inspection items are minimum items to guarantee long-term security usage of the press machine , Please increase inspection items according to the situation of your company

Regular inspection of oil (oil-supply and oil-change),please inspect according to maintenance instruction

The inspectors must inspect the items regularly, please inspect according to safety instruction, after inspection the inspectors would take certain corresponding measurement into effect.

Main Components List

| Dual Solenoid Valve For Clutch Unit | Made By TACO(Japan) |

| Overload Air Pump | Made By KINGAIR(Taiwan) |

| Automatic Grease Pump | Made By Lube |

| Programmable Logic Controller | Made By OMRON |

| Main Electrical Components | Made By TELEMECANIQUE |

| Main Pneumatic Components | Made By SMC(Japan) |

| Main Seal Rings | Made In Taiwan |

| Main Speed-Variable Motor | Made In China |

| Pneumatic Clutch-Brake | Made By OMPI (Italy) |

| Photo Electric Protector(Optional) | Made In China |