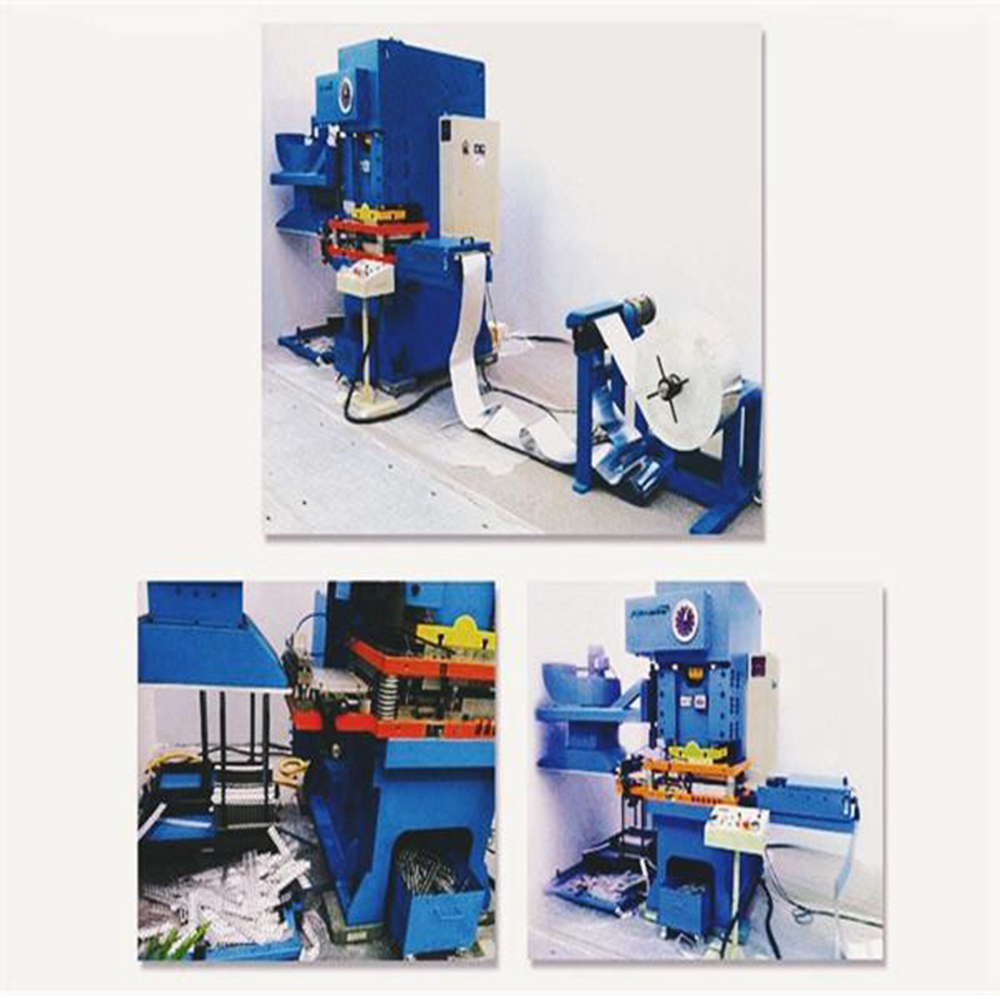

C Frame Air Conditioner High Speed Aluminum Press

Product Details

FIN PRESS The Satis 45/60 Ton, [C" Frame SFL Press Is Specifically Designed For Manufacturing Heat Transfer Fins. The Press Utilizes An Anti-Friction Bearing Design That Reduces The Required Running Clearances. This Precision Is Very Important For High Precision Achievement. A Programmable Controller Is Used To Control The Press.

Vibration Isolator Machine Mounts (4) Pcs. Are Included Which Eliminate The Need For Special Foundations.

Automatic Lubrication Is Provide Which Can Lubricate Every Key Bearings, Guide Ways And So On.

FIN STOCK UNCOILER The Uncoiler Is Designed Of Pinch Roll Feed Type. The Stock Coil Inside Diameter Is 150mm, Outside Diameter 1100 Mm Max. Coil Weight Is 1,000 Pounds

STOCK FAULT SENSOR This Is A Photo Sensor System That Will Detect Both End Of Stock At The Uncoiler And Tight Stock Between The Uncoiler And The Lube Tank.

STOCK LUBRICATOR We Propose To Furnish A Tank Dip Type Lubricator. The Stock Passes Through The Lubricant Guided By Rolls. Prior To Leaving The Tank, The Stock Passes Through Two Stripping Rolls Which Wipe Excess Lubricant Back Into The Tank. The Low Level Shut-Off Is Quoted To Protect The Die In The Event The Stock Lubricant Runs Out.

LUBRICATION LOW LEVEL SHUT OFF & WARNING SYSTEM A Low Level Detector Will Stop The Press If Fin Stock Lubricant Is Below A Preset Level.

LUBRICATOR AND STOCK GUIDE SUPPORTS This Is A Weldment Bracket To Support The Fin Stock Guide Plus The Fin Lubricator.

UPPER SUCTION UNIT AND SUCTION PLATE The Current Standard Upper Suction Unit Consists Of A Fan Driven By Power. The Suction Capacity Is Adjustable Via Transducer. Higher Capacity Units And Variable Speed Drives Can Be Designed Upon Request. Optional Double Blower Units Are Also Available For Extreme Material And Part Design Conditions And 36" Long Fin.

FIN STACKER, 2 POSITION SHUTTLE We Would Propose The Suction Drop To Rod Type Fin Stacker As 2 Position Shuttle (Trolley) Design . Using A Counter On The Press, The Press Will Stop When A Predetermined Amount Of Fins Have Been Countered Out By The Press.

SINGLE ROW FIN OPTION Single Row Fins Is An Option For Your High Efficient Manufacturing Purpose. A Fin Blow Down Unit Is Used To Assist To Push The Fins Away From The Suction Drop. It Is Important With Enhanced Fin Configurations Which Are Very Light And Tend To Not Release From The Suction Drop Properly.

SCRAP AND TRIM COLLECTION UNIT Scrap Tanks Are Furnished To Be Used For Scrap Collection For Convenient Operation.

Fin Press Specifications

Capacity: 450KN

Strokes per Minute: 100-180 spm

Stroke of Slide: 40mm

Die Height Adjustment: 70mm

Max. Die set height: 270mm

Bolster Area (LR x FB x Thickness): 800x580x80mm

Bolster Area: (LR x FB): 500x300mm

Fin Pattern: The buyer supply the drawing

Be equipped with moving scrap box.

Be equipped with lubrication unit, to prolong die’s life.

Lubricating method of die guide pillars: Manual thin oil lubrication pump

Operation method: moving operation panel

Decoiler Specifications

Type: Conicity distended type

Material: Aluminum Coil

Max. Outer Diameter of Coil: Φ850 mm

Inner Diameter of Coil: Φ75±5 mm

Max. width of coil: 300mm

Feeding direction: from right to left

Oil Tank & Conducted Coil-Feeding

Type: oil-bathed type

Conductor type: retainer ring moving

Aluminum-coil suppressed type: roller

Oil collecting device under the oil tank

Vacuum Sucker And Collection Unit

Type: sucked automatically by vacuum air with close/open

Sucking Adjustment: Adjust the plate of vacuum sucker’s exit

Sucking area: W300xL1000

Collection type: Double-seat moving unit

Collection moving: Manual Type

Size fins of collecting plate: W300xL1000

Collecting height of material: 600mm

Main Parts Brands

| Clutch Valve | Made By MAC (The USA) |

| Electromagnetic | FESTO AND SMC |

| PLC | OMRON |

| SWITCH | SCHNEIDER |

| CONTACTOR | ABB |

| LUBRICATION PUMP | JONGJIA-LUBE |

| Display Unit | DELTA |