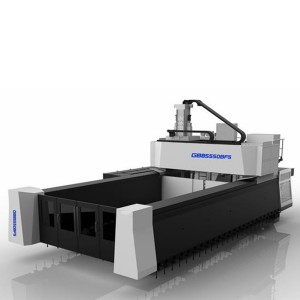

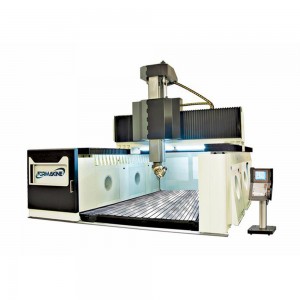

Bridge Type Gantry Machining Center

Product Description

Bridge type gantry machining center is with frame structure, with grinding sliding guide, according to a good rigidity, strong shock absorption, processing a wide range of good stability, the machine with milling, boring, drilling (drilling, expansion, hinge), tapping, Countersink and other processing functions, can be equipped with a variety of accessories milling head, with manual change function, to expand the processing range of the machine, parts can be completed at the same time a number of processing steps.

The product structure and process maturity, quality and stability. Applicable to the automotive, ship, printing, packaging, textile, military, mold and other mechanical processing areas. Machine tools with high efficiency, high precision, high rigidity and other characteristics, is the enterprise efficient, high-volume parts of the ideal choice.

Standard Equipment

| No. | Item | Model | Brand |

| 1 | CNC System | Fanuc 0i MD | |

| 2 | X Axis Ballscrew | HIWIN-Taiwan | |

| 3 | Y Axis Ballscrew | HIWIN-Taiwan | |

| 4 | Z Axis Ballscrew | HIWIN-Taiwan | |

| 5 | Heavy Load Linear Guideway | Roller Type | HIWIN-Taiwan |

| 6 | Heavy Load Linear Guideway | Roller Type | HIWIN-Taiwan |

| 7 | Bearing For Screwbar | SKF-Germany | |

| 8 | Tool Magazine(Option) | 32station | Gifu-Taiwan |

| 9 | Air Condition | Leibo | |

| 10 | Spindle | Kenturn Nano-Taiwan | |

| 11 | Clamping System For Tools | Kenturn Nano-Taiwan | |

| 12 | Hydraulic Parts | Shenyu-Taiwan | |

| 13 | Chip Conveyor | Xinyu-Yantai | |

| 14 | Electric Units | Siemens/Scheider/ABB |

Technical Specifications

|

Main Data |

|

Unit |

FMG1220 |

FMG1230 |

FMG1240 |

FMG1630 |

FMG1640 |

FMG1650 |

|

| Work Table | Table Size |

Mm |

1250X2000 |

1250×3000 |

1250X4000 |

1600×3000 |

1600×3000 |

1600×3000 |

|

| Distance Between 2 Columns |

Mm |

1450 |

1450 |

1450 |

2100 |

2100 |

2100 |

||

| Max. Load |

Kg |

3000 |

5000 |

7000 |

7000 |

8500 |

10000 |

||

| T-Slot Width |

Mm |

22H12 |

22H12 |

22H12 |

22H12 |

22H12 |

22H12 |

||

| Machining Range | X-Axis Travel |

Mm |

2200 |

3200 |

4200 |

3200 |

4200 |

5200 |

|

| Y-Axis Travel |

Mm |

1250 |

1250 |

1250 |

2300 |

2300 |

2300 |

||

| Z-Axis Travel |

Mm |

750 |

750 |

750 |

1000 |

1000 |

1000 |

||

| Distance From Spindle Nose To Table Surface | Min |

Mm |

200 |

200 |

200 |

200 |

200 |

200 |

|

| Max. |

Mm |

950 |

950 |

950 |

1200 |

1200 |

1200 |

||

| Spindle | Taper (7:24) |

|

BT50 |

BT50 |

BT50 |

BT50 |

BT50 |

BT50 |

|

| Inner Dia. Of Front Bearing |

Mm |

Φ100 |

Φ100 |

Φ100 |

Φ100 |

Φ100 |

Φ100 |

||

| Lubrication Type |

|

Grease |

Grease | Grease | Grease | Grease | Grease | ||

| Speed-Change |

|

2 Steps/Infinite |

|||||||

| Ratio |

|

1:1/1:4 |

1:1/1:4 |

1:1/1:4 |

1:1/1:5.5 |

1:1/1:5.5 |

1:1/1:5.5 |

||

| Speed Range |

R/Min |

40~6000 |

40~6000 |

40~6000 |

40~6000 |

40~6000 |

40~6000 |

||

| Motor Power | Min. |

KW |

18.5 |

18.5 |

18.5 |

22 |

22 |

22 |

|

| Max. |

KW |

22 |

22 |

22 |

26 |

26 |

26 |

||

| Max. Torque | Min. |

N·m |

470 |

470 |

470 |

770 |

770 |

770 |

|

| Max. |

N·m |

560 |

560 |

560 |

910 |

910 |

910 |

||

| Feed | Cutting Feed Speed Range |

Mm/Min |

1~10000 |

1~10000 |

1~10000 |

1~12000 |

1~12000 |

1~12000 |

|

| Fast Speed | X-Axis |

M/Min |

20 |

20 |

20 |

20 |

20 |

20 |

|

| Y-Axis |

M/Min |

20 |

20 |

20 |

20 |

20 |

20 |

||

| Z-Axis |

M/Min |

16 |

16 |

16 |

16 |

16 |

16 |

||

|

ATC |

Tool Magazine Capacity |

Pieces |

32,40,50,60 |

32,40,50,60 |

32,40,50,60 |

32,40,50,60 |

32,40,50,60 |

32,40,50,60 |

|

| Max. Tool Length |

Mm |

400 |

400 |

400 |

400 |

400 |

400 |

||

| Max. Tool Weight |

Kg |

25 |

25 |

25 |

25 |

25 |

25 |

||

| Tools Chooseing |

|

Random |

|||||||

| Max. Tool Dia. |

Pieces |

Φ125 |

Φ125 |

Φ125 |

Φ125 |

Φ125 |

Φ125 |

||

|

Pieces |

Φ250 |

Φ250 |

Φ250 |

Φ250 |

Φ250 |

Φ250 |

|||

Picture Display

Professional Testing

We owns more than 632sets of production equipments, some world famous brand like Germany DMG horizontal

machining center, Germany Trumpf laser cutting machine and bending machine, America floor tye boring machine,

Shanghai C N C gantry guide rail grinding machine, Beijing C N C gantry type boring milling machine and automatic

powder coating line .Besides, C N C machine tool project laboratory with advanced testing equipments is built for quality control.

We will test every machines carefully in different status by our professional engineers to make sure our machinesquality. For linear guides cnc milling machine, we will test the accuracy by Renishaw laser interferometer and will make ball bar test, as well as cutting test before delivery.With the sequence testing, we can make sure the machines' quality.

Packing & Shipping

Optional Accessories

The machine can be equipped with many accessories to carry out different works. Mostly, the machine can be equipped with the 4th axis rotary table or dividing head, we can supply China brand and Taiwan brand, it can be equipped with tool setting probe. You can use tool setting probe to measure tool length,diameter etc. And you can also choose screw type chip conveyor or chain type conveyor.

You can choose all the optional accessories according to your demand. If you need any other accessories, we can talk in details, we will try our best to satisfy all your request.

Processing Equipment