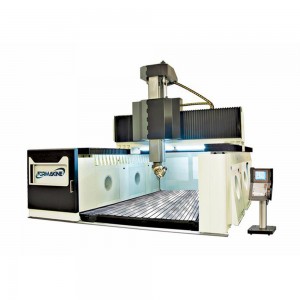

Bridge Type 5 Axis Gantry Machining Center

Product Features

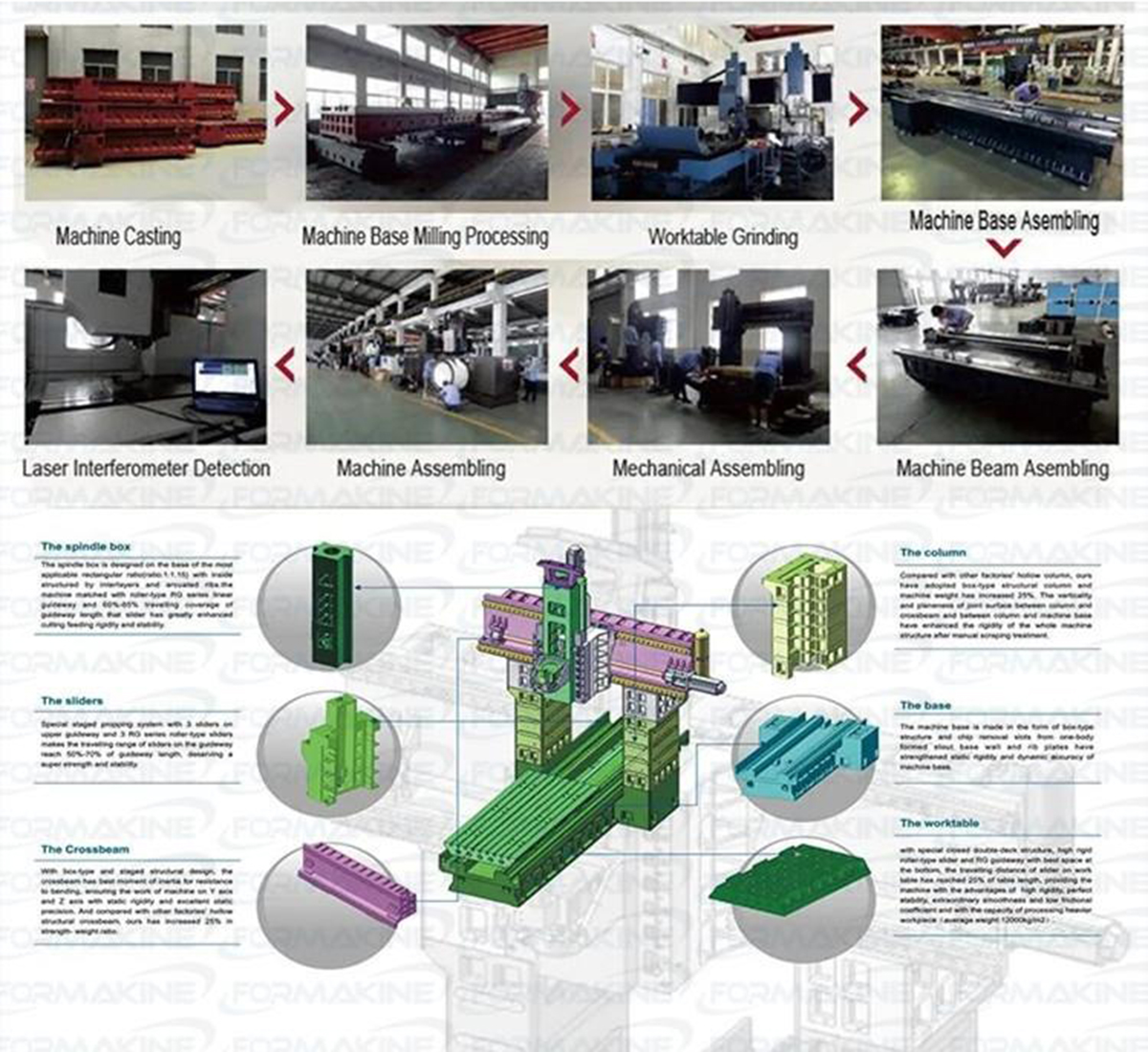

1. The Machine body (i.e.:Base, columns, crossbeams and etc) is made of high grade cast iron,the layout of reinforcing rib plate analysis and calculated by rigid optimization, and with years of experience to set effective annealing process to eliminate residual stress, so that to keep machine accuracy stablely and effectively for a long time.

2. The machine body and column structure made by Honeycomb type casting,To improve the rigidity and long - term precision effectively.

3. Adopt advanced working machine (large size imported gantry machining center and guide rail grinding machine), achieved required process accuracy, laid a good foundation for assembly.

4. The bearings of Three axis screw rods fixed by imported high precision lock nut to ensure assembly precision.

5. Match with high speed and high precision CNC controller, standard with colorful LCD screen, Ethernet network interface, USB port, dynamic graphical simulation display, Various special Higher functions,i.e.:interpolation and others functions can meet all kinds of requirements effectively.

6. All components are verified by long-term usage, can ensure the reliability in machine long-term running.

7. Sophisticated Quality testing, with advanced three coordinate measuring instrument, imported laser interferometer, the Ballbar, on-line dynamic balancing instrument precision testing instruments, to ensure the performance of the machines we produced can meet the function and design requirements.

8. Experienced research and development team, breakthrough old ways of thinking, assist customers to achieve various special needs.

9. Experienced and warm-hearted service team, can effectively ensure the best working condition for the user's machine.

Technical Specifications

| Item | Unit | FGT-1190 | FGT-1311 | FGT-1612 | FGT-1713 | FGT-2215 | FGT-2616 |

| Worktable | |||||||

| Worktable Size | Mm | 1200×900 | 1300×1000 | 1600×1200 | 1700×1200 | 2200×1480 | 2600×1480 |

| Max.Loading On Table | KG | 1000 | 2000 | 2000 | 3000 | 6000 | 8000 |

| Travel | |||||||

| X Axis Travel | Mm | 1100 | 1300 | 1600 | 1700 | 2200 | 2600 |

| Y Axis Travel | Mm | 900 | 1100 | 1200 | 1300 | 1500 | 1580 |

| Z Axis Travel | Mm | 600 | 600 | 580 | 700 | 800 | 800 |

| Spindle Nose To Table | Mm | 150-750 | 150-750 | 240-820 | 250-950 | 150-950 | 350-1150 |

| Distance Between Column | Mm | 1060 | 1200 | 1350 | 1350 | 1580 | 1620 |

| Feed System | |||||||

| XYZ Rapid Feed | M/Min | 20/15/10 | 15/15/7.5 | 15/15/7.5 | 15/15/7.5 | 15/15/7.5 | 15/15/7.5 |

| Cutting Feed | M/Min | 10 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 |

| Accuracy | |||||||

| Positioning Accuracy | Mm | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 |

| Re-Positioning Accuracy | Mm | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 |

| Spindle | |||||||

| Spindle Speed | Rpm | 15000/20000 | 15000/20000 | 15000/20000 | 15000/20000 | 15000/20000 | 15000/20000 |

| Spindle Taper | HSK-A63 | HSK-A63 | HSK-A63 | HSK-A63 | HSK-A63 | HSK-A63 | |

| Others | |||||||

| Footprint | Mm | 3100×2350 | 3800×2300 | 4300×2400 | 5000×2500 | 6000×2800 | 6800×2800 |

| Machine Height | Mm | 2900 | 3000 | 3000 | 3200 | 3300 | 3500 |

| Machine Weight | KG | 8000 | 10500 | 11000 | 16000 | 18000 | 23500 |

| CNC Controller | FANUC-0i MF | FANUC-0i MF | FANUC-0i MF | FANUC-0i MF | FANUC-0i MF | FANUC-0i MF |

Optional Configuration

| Standard | Options |

| FANUC CNC Controller System | 24/32/40T ATC/Tool Magazine |

| Auto.Lubricating Device | CTS 20/30/40 Bar |

| Outer Protective Guard Cover | 4 th Axis CNC Rotary Table |

| LED Working Lamp | 5 th Axis CNC Tilting and Rotary Table |

| Spindle Blowing Device | 5 Axis AC Bi-Rotary milling Head for 5 axis machining |

| Hand type Air Gun | Linear Scale |

| Electric Control Cabinet | Spindle Gearbox for heavy duty machining |

| Transformer | Spindle Oil Cooling Device |

| Air Conditioner for Electric Cabinet | 90 degree milling head realizes 5-face machining |

| Air gun & water gun | Universal milling head realizes multi-angles machining |

| Manual Pulse Generator(MPG) | Automatic Tool touch sensor, improve work efficiency |

| High Speed Spindle | Automatic Workpiece measuring system |

| Warning Lamp | Chain type chip conveyor outside |

| Cutting fluid system | Linear Scales realizes closed loop control |

| Air pressure system | Siemens/Mitsubishi/Heidenhain/LNC/SYNTEC CNC Controller |

| Screw type chip removal system Inside | Any others option as your requested. |

| Heavy-load linear guide rails | |

| Foot control for releasing tool device(Size≥BT50 Type) | |

| RS232 connector and DNC connector | |

| Operating Manual |

Our Factory

Package & Transportation