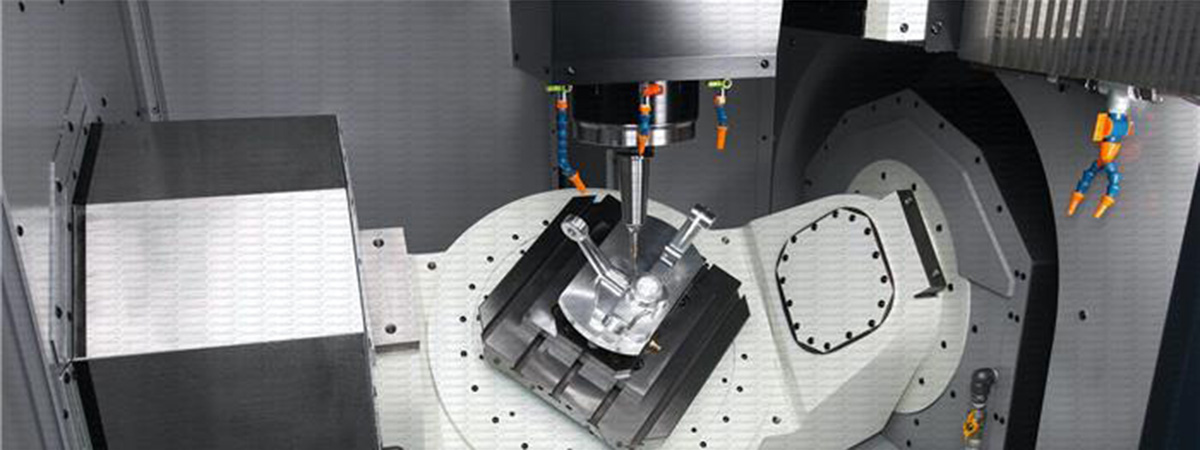

5 Axis Vertical Machining Center

Product Description

Vertical Metal Hardware Processing Machining Center (5-axis) CNC Machine

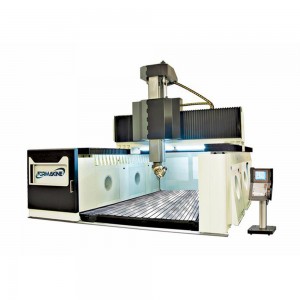

CNC Machine, CNC Machining Center, CNC Lathe, Horizontal Machining Center, Gantry Machining Center, Five-Axis Machining Center, High Speed Driliing and Tapping Machine, Turning-Milling Compound Machine, High Speed Vertical Machining Center, Hard Track Machining Center, Knife Arrangeing Machine, Knife Tower Machine, Knife Tower Tailstock Machine.

Processing Application:

Hardware, Mold, Automotive, Communications, IT Industry, Medical Equipment, Aerospace.

Machine Features:

1. The bed is structurally strong and can withstand the inertia generated by high-speed motion.

2. The 5-axis adopts high-speed silent screw and silent line rail to make the heat displacement less accurate.

3. The column is designed to be elevated, and the fourth and fifth axis spaces are reserved.

4. The imported 5-axis shield protects the screw line rail and increases the service life of the machine.

Technical Parameters

|

Specifications |

Unit |

VMC7032 |

|

Table Size (L*W) |

Mm |

800×320 |

|

Travel Of X,Y,Z Axis |

Mm |

610/320/400 |

|

Max, Table Load |

Kg |

400 |

|

T-Slot Size |

Mm |

3-14-100 |

|

Center Distance |

Mm |

100 |

|

Spindle Taper |

-- |

BT40 |

|

Spindle Center To Column Guide Distance |

Mm |

376 |

|

Spindle End Face To Table Distance |

Mm |

130-530 |

|

Max Speed |

Rpm |

8000 |

|

Spindle Motor Power |

KW |

3.7/5.5 |

|

Spindle Drive |

-- |

Belt Transmission |

|

Positioning Accuracy |

Mm |

0.015 |

|

Repeat Positioning Accuracy |

Mm |

0.0075 |

|

Rapid Feed Of X/Y/Z |

Mm/Min |

1000 |

|

Cutting Feed Of X/Y/Z |

Mm/Min |

6000 |

|

Tool Magazine Capacity |

Tools |

12 |

|

Max. Tool Size |

Mm |

100 |

|

Max. Tool Weight |

Kg |

8 |

|

Machine Weight |

Kg |

3000 |

|

Dimension |

Mm |

2280*1760*2200 |

|

Power |

-- |

3 Phase 380V, |

Optional Configuration

1. System: KND2000M, FANUC, Siemens etc.

2. Spindle speed: 10000rpm

3. Fourth axis with 125°dividing head

4. Fifth axis

5. 16 pieces arm type ATC

Our Factory

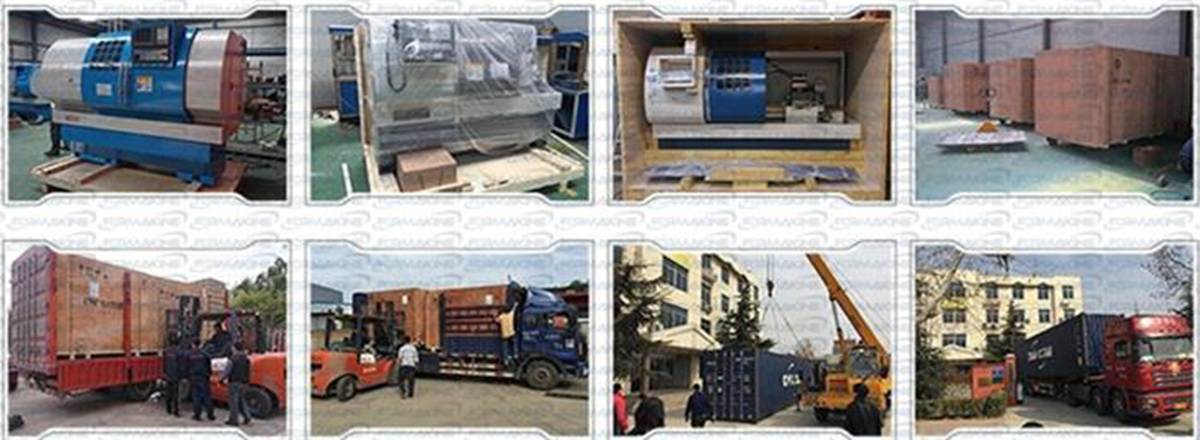

Packing & Shipping