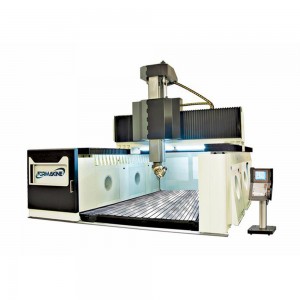

5 Axis Gantry Machining Center

Product Features

1. This machine is designed for mold making,ship,rail traffic,car buffer beam,photovoltaic,aluminum window door and curtain wall industry aluminum structure parts processing.It is also the ideal machine to suitable for high precision processing,complicated parts and mould making industry,aerospace project.

2. Adopt Taiwan SYNTEC 5 axis CNC control system with RTCP function,imported servo motor and driver,so can make sure the function of fast position and stable working.

3. The CNC system has file storage unit, can store more than ten thousands different program files. The operators feel convenienct to use them during production. The CNC system has the functions of fault detection, break point recovery, power failure recovery etc. The control system adopts a modular structure which facilitates the service and maintenance at the production site.

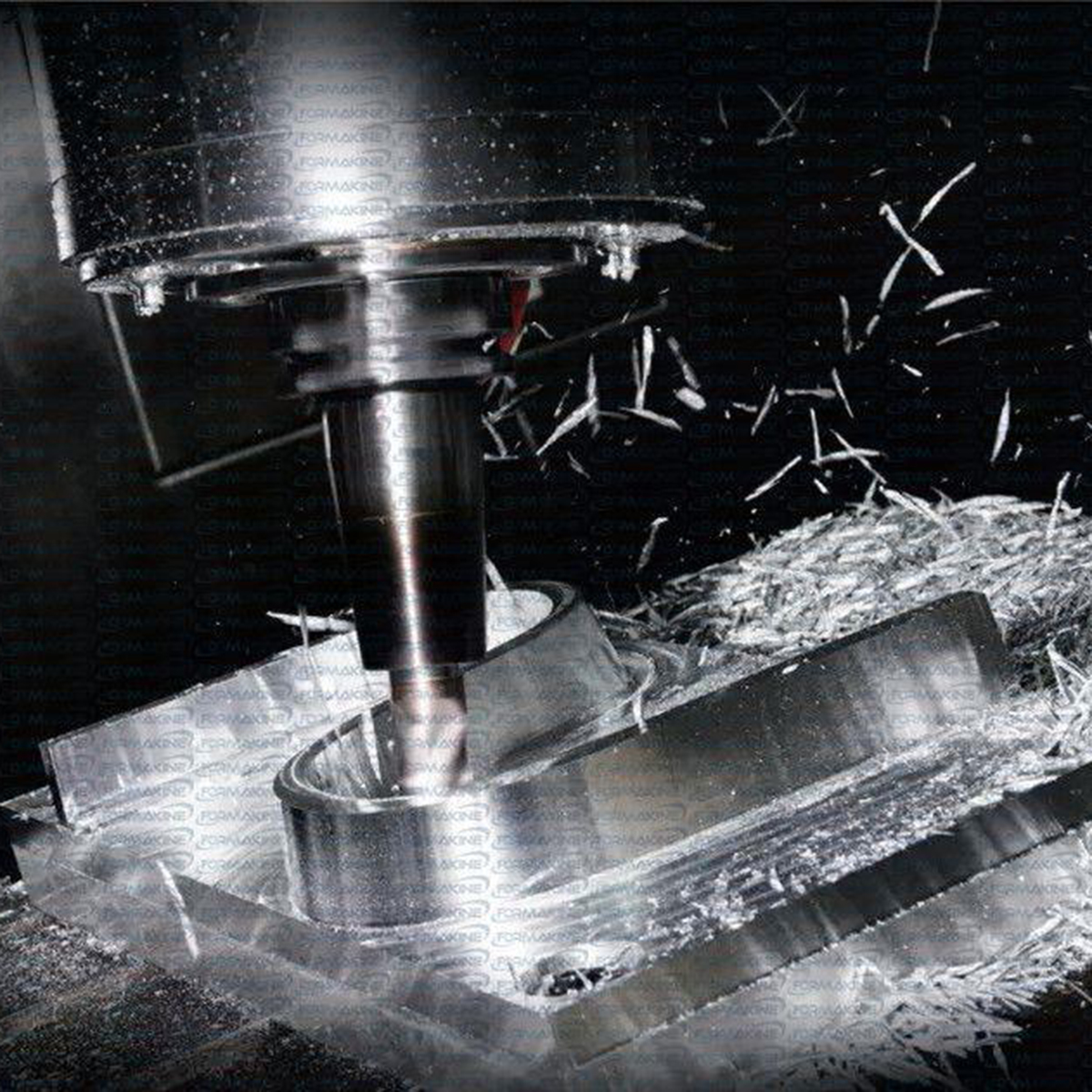

4. Adopt advanced CNC control system, the machine can meet various processing requirements,such as drilling, milling, rigid tapping and sawing.

5. Five-Axis spindle adopts Italy 12KW automatic tool change and tool aligning function. Realizing multi-face and multi-angle process on kinds of aluminium profile. With cutting function can realize precisely cutting at multiface and multi-angle.

6. 16 tools magazine, disc 8 tools and linear 8 tools,meeting the requirement of quick tool changing in different hole positions of profile processing.

7. With spray cooling function, improve profile surface processing quality and extend tool life.

8. The designed system software and post treatment, Can meet the requirement of high precision for different process, It is very easy to operate.

9. It can achieve dual-zone working model,means one zone is working, at the same time the other zone is loading/uploading parts. Machine can achieve alternating working.

10. Machine body frame was treated by overall heavy-duty welding, And it is satisfied with the standard of CNC Milling design, overall machine was processed by the CNC Machining center after heat treatment. The machine gantry structure adopts overall welding. It has the advantages of high precision, stable structure and longer service life etc.

Technical Specifications

| Parameter | Unit | Screw And Pinion Drive Type | Linear Electric Drive Type |

| X-Axis Travel | Mm | 2000/2500/3000 | 2000/2500/3000 |

| Y-Axis Travel | Mm | 1500/2000/2500/3000/4000 | 2500/2000/2500/3000/4000 |

| Z-Axis Travel | Mm | 750/1000/1400 | 750/1000/1400 |

| Spindle End To Table Distance | Mm | 50*180 | 50*180 |

| Workbench Length | Mm | 2000/2500/3000 | 2000/2500/3000 |

| Workbench Width | Mm | 1500/2000/2500/4000 | 1500/2000/2500/4000 |

| T-Slot | Mm | 28 | 28 |

| Workbench Maximum Load | Kg/M2 | 8500 | 8500 |

| Swing Head Specification | GM345.01 | GM345.01 | |

| A/C-Axis Swing Range | ° | 110/360 | 110/360 |

| A/C-Axis Maximum Speed | Nm | 60 | 60 |

| A/C-Axis Clamping Torque | Nm | 2000 | 2000 |

| A-Axis Rated TorqueS1 | Nm | 800 | 800 |

| A-Axis Max.Rated Torque | Nm | 1200 | 1200 |

| C-Axis Rated TorqueS1 | Nm | 1000 | 1000 |

| C-Axis Max.Rated Torque | Nm | 1500 | 1500 |

| Swing Arm Length | Mm | 327 | 327 |

| X/Y Fastest Moving Speed | M/Min | 24 | 50 |

| Z Fastest Moving Speed | M/Min | 20 | 40 |

| X/Y/Z Fastest Feed Speed | M/Min | 20 | 20 |

| X/Y/Z Maximum Acceleration | N/S2 | 4 | 6 |

| X/Y/Z Positioning Accuracy | Mm | ||

| X/Y/Z Repeat Positioning Accuracy | Mm | ||

| A/C Positioning Accuracy | ° | 6 | 6 |

| A/C Repeat Positioning Accuracy | ° | 5 | 5 |

| Spindle Shank Standard | Kw | HSK-A63 | HSK-A63 |

| Spindle Power | Rpm | 30 | 30 |

| Spindle Rated Speed | Rpm | 3400 | 3400 |

| Spindle Max. Speed | Nm | 18000 | 18000 |

| Spindle Rated Torque | Nm | 84 | 84 |

| Spindle Maximum Torque | Nm | 120 | 120 |

| Tool Magazine Capacity | One | 20/40/60 | 20/40/60 |

| Maximum Diameter Of The Tool | Mm | 75/120 | 75/120 |

| Maximum Length Of Tool | Mm | 230 | 230 |

| Tool Weight | Kg | 6 | 6 |

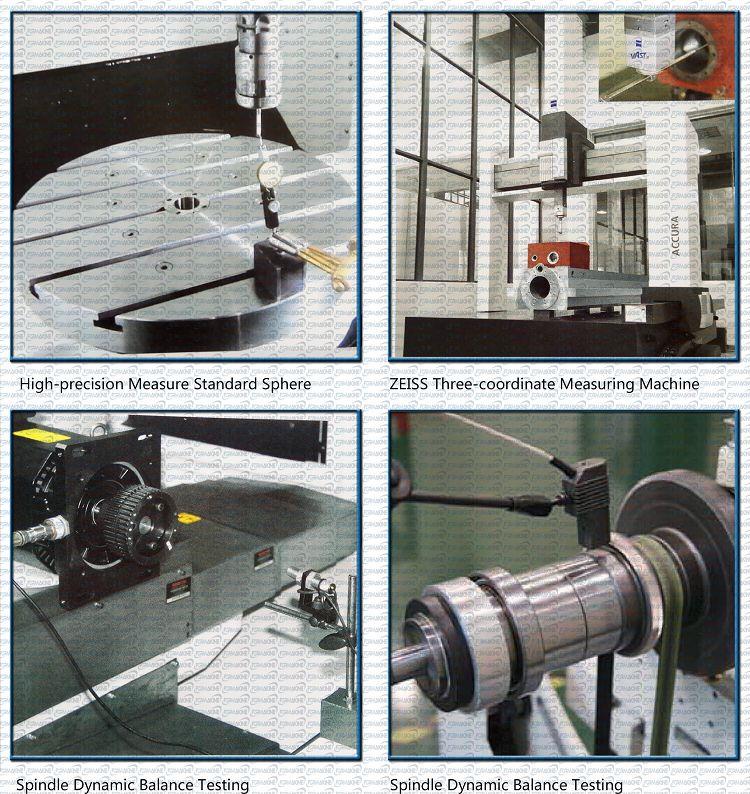

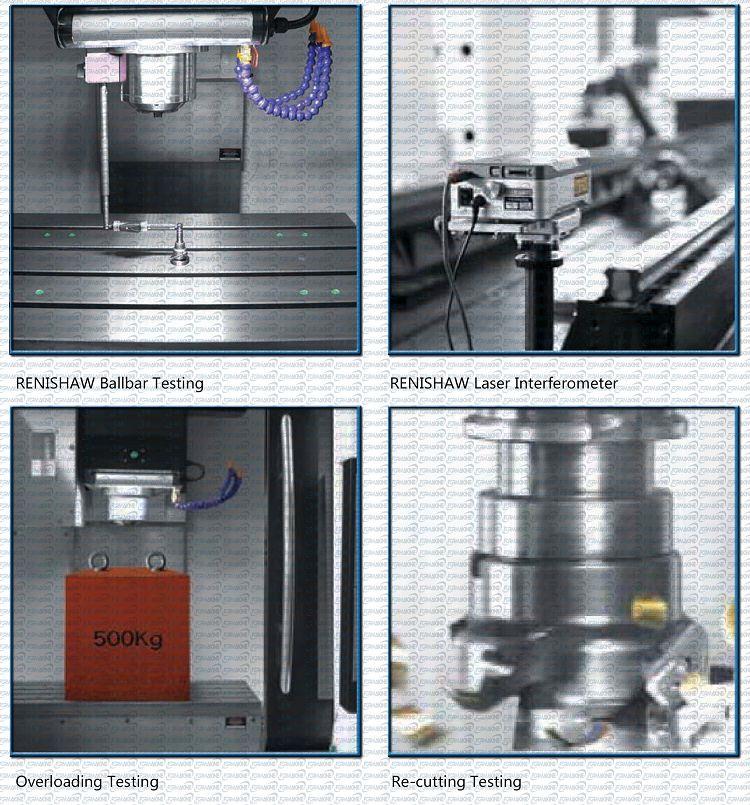

Testing Process Control

The company implemented strict internal standards for quality assurance, and realized the strict monitoring of the whole product design and manufacture process with over 40 test items, over 600 quality control points ,48-hour high-speed total travel load processing test and the world’s top-level precise testing equipment such as ZEISS three-coordinate measuring machine, RENISHAW laser interferometer and the spindle dynamic balance measuringmachine, they can also help to guarantee the accurate control of all details of the machine tool.

Reliable System

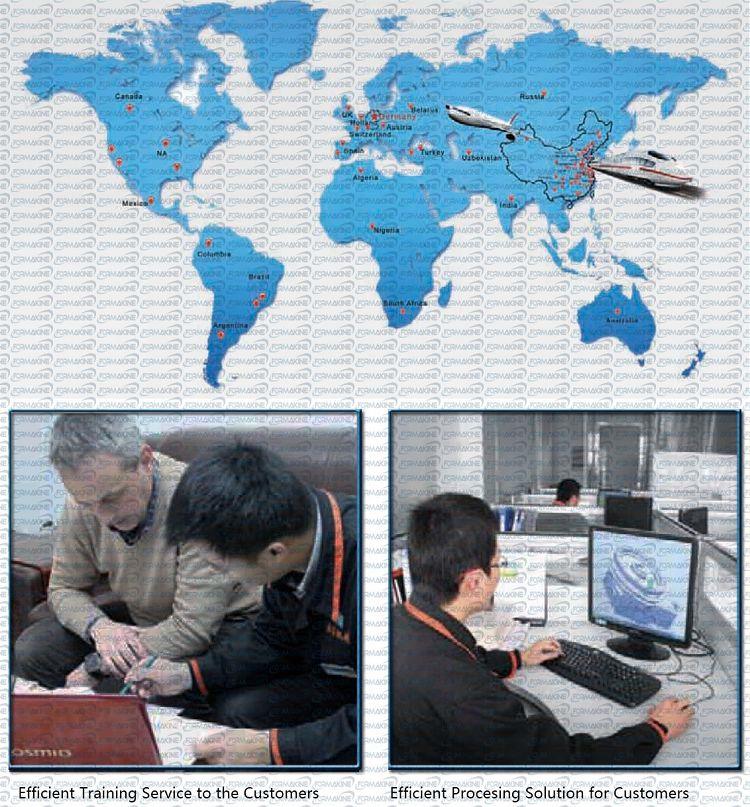

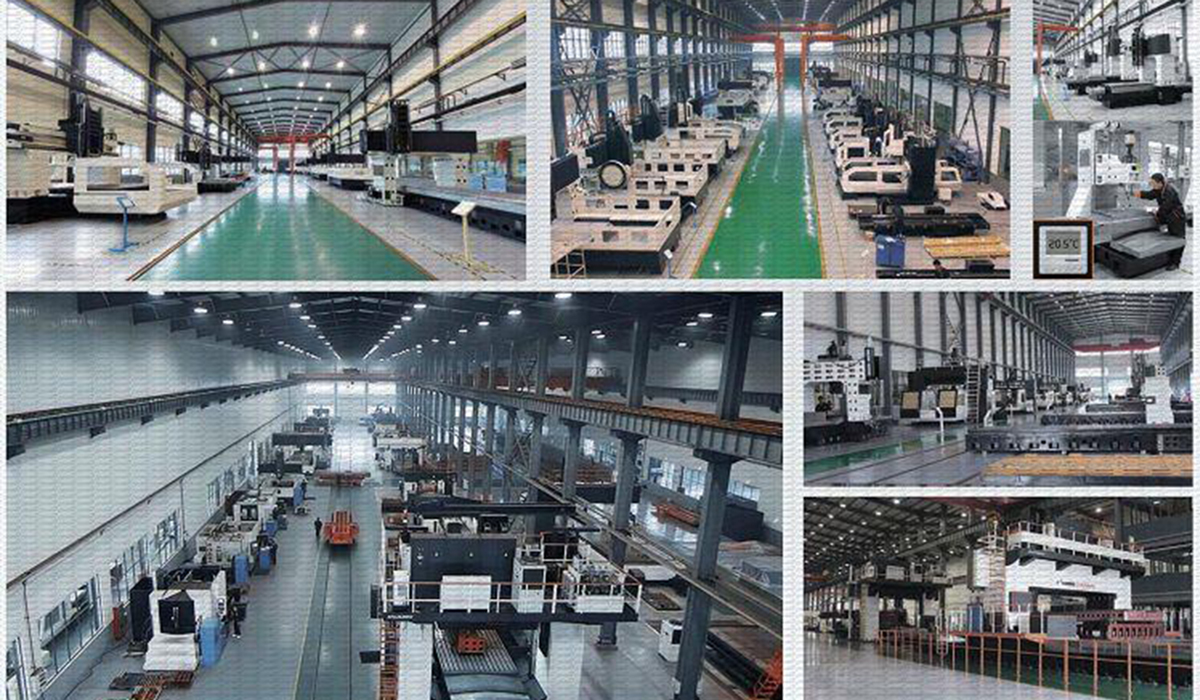

Our Company

We committed to R&D ,manufacture and sales of high-quality machines, main products including CNC machine tool, such as high-speed vertical machining center,large gantry machining center, heavy portal boring and milling machine , high-precision milling &boring machining center and 5-axis machining center etc. also we supply CNC Lathe,Grinding Machines,Boring Machines, Lathe,Manual Lathe,Wire EDM Machines,CNC Milling Machine,and other machine tools.

15000 Square meter Constant Temperature Dust-free Assembly Plant and Large Milling Plant.

Picture Display

Shipping & Packing