4 Point Transfer Stamping Press

Product Description

Transfer(Multi-station) press can replace the production line composed of multiple large presses, realize the automatic workpiece conversion station according to the process sequence requirements, the maximum production cycle reaches 30 times / minute, high production efficiency, high degree of automation, mold change time Short, small footprint, to meet the automotive industry's demand for high-grade, high-efficiency stamping equipment.

The closed transfer (multi-station) press is an advanced equipment for efficient and large-scale stamping production. It integrates mechanical, electronic, control and inspection technologies to achieve high-speed, high-precision and full automation of stamping production, representing the current international stamping The high-end technology level.

Closed multi-station presses are suitable for various industrial sectors such as automobiles, agricultural machinery, bearings, motors, electrical appliances, light industry, textile machinery, and weapons. This kind of press can complete multiple processes in one working stroke, such as blanking, punching, stretching, bending, cutting, correction, etc. It is a high-efficiency press; compared with ordinary presses, multi-station The press has the advantages of automatic loading and unloading, high material utilization rate, low energy consumption, high production efficiency, small press area and low production cost, and is very suitable for mass production.

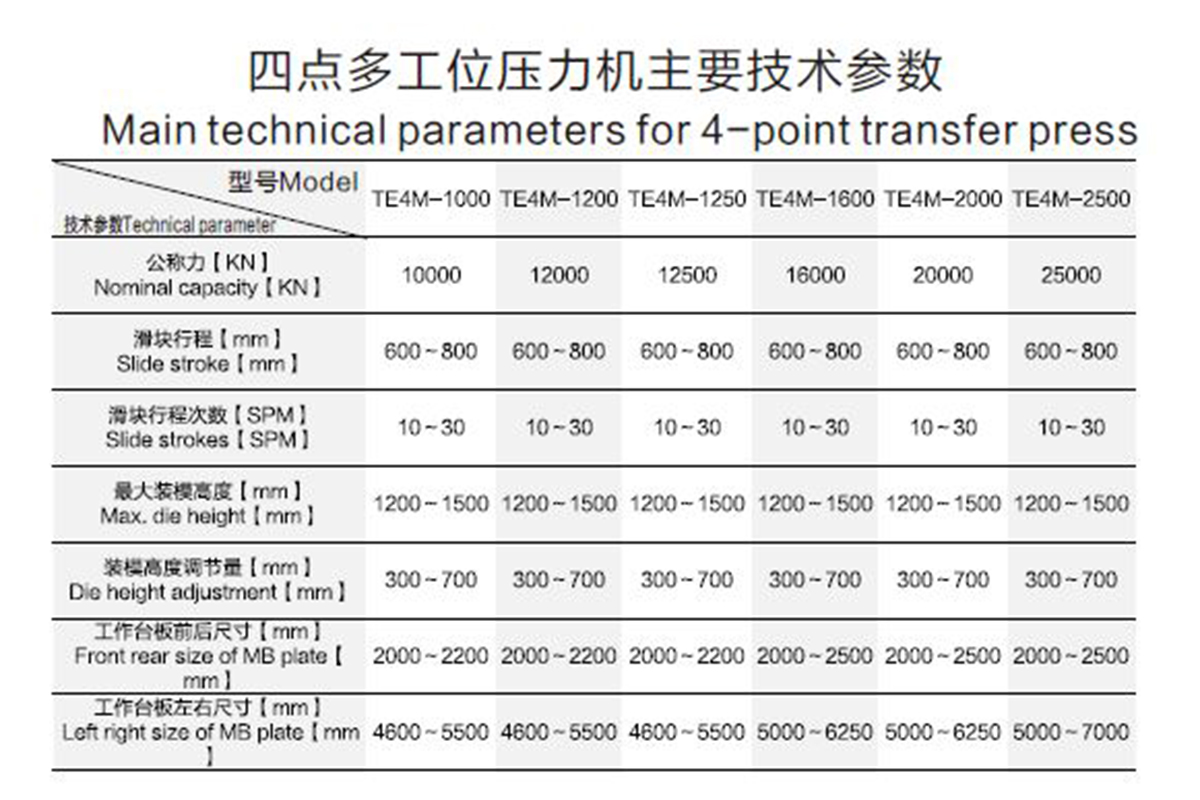

Technical Specifications